Advanced Digital Printing and Design Versatility

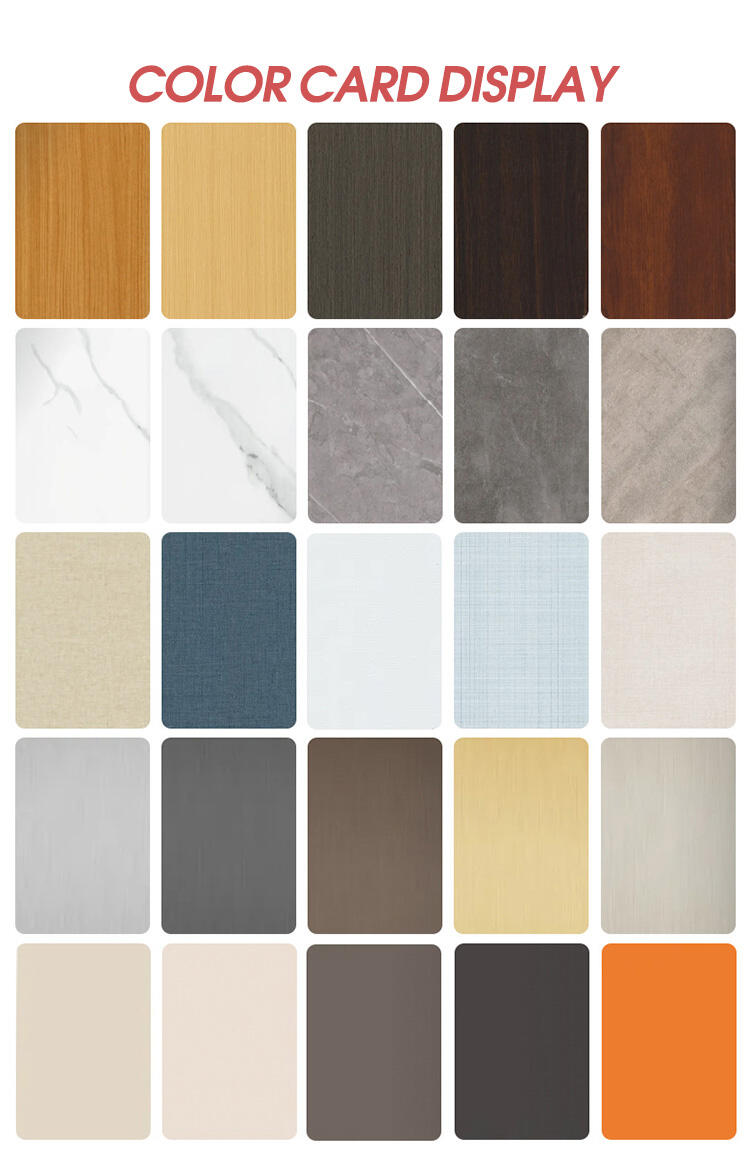

The sophisticated digital printing technology integrated into printed PVC wall panels enables unprecedented design flexibility and customization options that transform ordinary spaces into extraordinary environments. High-resolution printing capabilities reproduce intricate details, subtle color gradations, and complex patterns with photographic quality that rivals expensive natural materials or hand-crafted finishes. This technological advancement allows architects, designers, and property owners to achieve premium aesthetic results without the cost, maintenance, or installation challenges associated with authentic materials like marble, wood grain, or decorative stone. The printing process utilizes UV-resistant inks and protective topcoats that maintain color vibrancy and prevent fading even under continuous exposure to fluorescent lighting or natural sunlight, ensuring that printed designs retain their original appearance throughout the product lifecycle. Customization possibilities extend to corporate branding applications, where logos, color schemes, and marketing messages can be incorporated directly into wall surfaces, creating cohesive branded environments in retail stores, restaurants, or office complexes. The digital printing technology accommodates both standard pattern repeats and continuous imaging across multiple panels, enabling large-scale murals, landscapes, or artistic compositions that create dramatic focal points in interior spaces. Color matching capabilities ensure consistency with existing design elements, allowing printed PVC wall panels to complement flooring, furniture, or architectural features seamlessly. The printing process maintains dimensional accuracy and registration precision, preventing color shifts or alignment issues that might occur with traditional manufacturing methods. Special effects including metallic finishes, textural elements, and three-dimensional appearances can be achieved through specialized printing techniques that add visual depth and tactile interest to flat surfaces. Design libraries from leading manufacturers include thousands of standard patterns ranging from contemporary geometric designs to classical architectural motifs, providing immediate access to professional-quality options for any design aesthetic. Custom design services accommodate unique requirements, enabling reproduction of historical patterns, site-specific imagery, or proprietary designs that reflect individual preferences or brand identities.