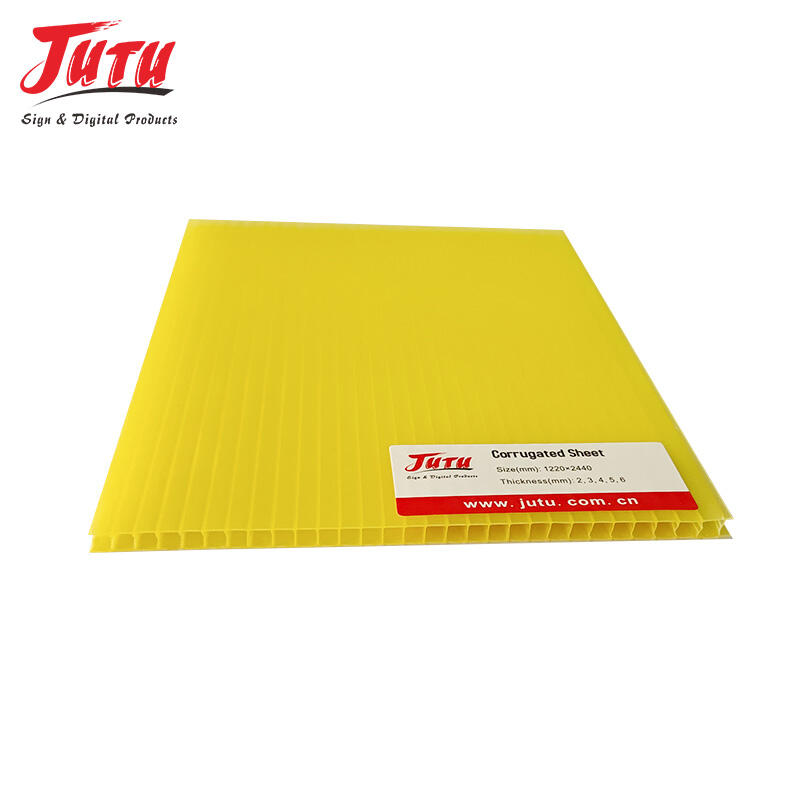

pp corrugated sheet manufacturer

A pp corrugated sheet manufacturer specializes in producing polypropylene corrugated sheets, which are lightweight yet durable plastic materials featuring a distinctive fluted core structure. These manufacturers utilize advanced extrusion technology and precision molding techniques to create sheets that combine exceptional strength-to-weight ratios with outstanding chemical resistance. The corrugated design consists of parallel ribs or flutes that run between two flat surfaces, creating a honeycomb-like internal structure that provides remarkable rigidity while maintaining flexibility. Modern pp corrugated sheet manufacturer facilities employ state-of-the-art equipment including twin-screw extruders, calibration tables, and automated cutting systems to ensure consistent quality and dimensional accuracy. The manufacturing process involves melting polypropylene resin, extruding it through specially designed dies, and cooling the material to form the characteristic corrugated profile. These manufacturers typically offer customization options including various thicknesses ranging from 2mm to 10mm, different colors, surface treatments, and printing capabilities. Quality control systems monitor density, impact resistance, and structural integrity throughout production. Leading pp corrugated sheet manufacturer companies maintain ISO certifications and follow strict environmental standards in their operations. The technological features include corona treatment for enhanced printability, UV stabilization for outdoor applications, and antistatic properties for electronic packaging. Advanced manufacturers also incorporate recycled content while maintaining product performance standards. The production capacity varies significantly among manufacturers, with larger facilities capable of producing thousands of square meters daily. These companies serve diverse industries including automotive, construction, agriculture, and packaging sectors, providing solutions that meet specific regulatory requirements and performance criteria for each application area.