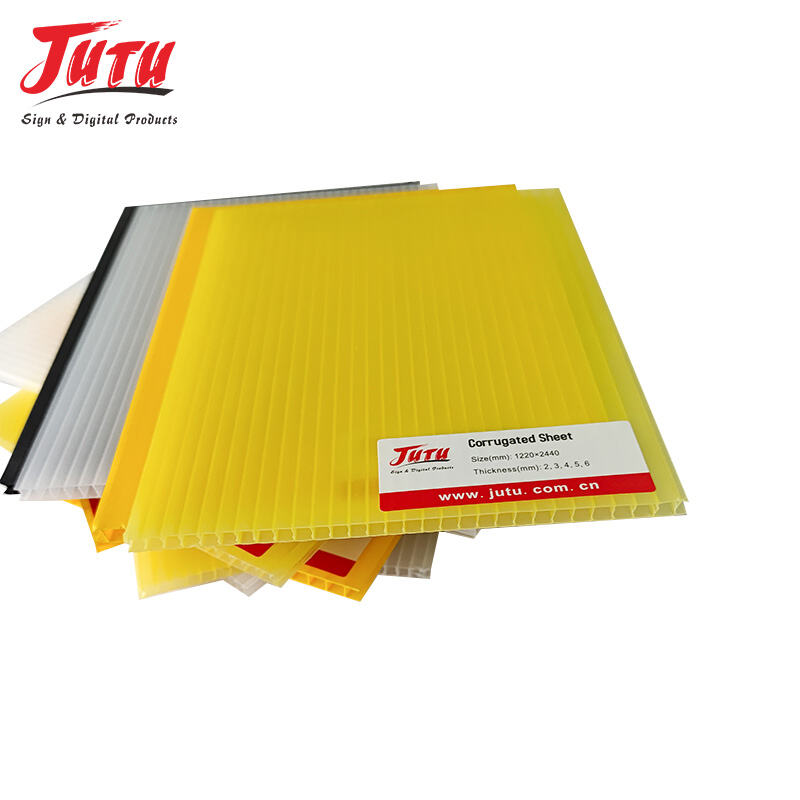

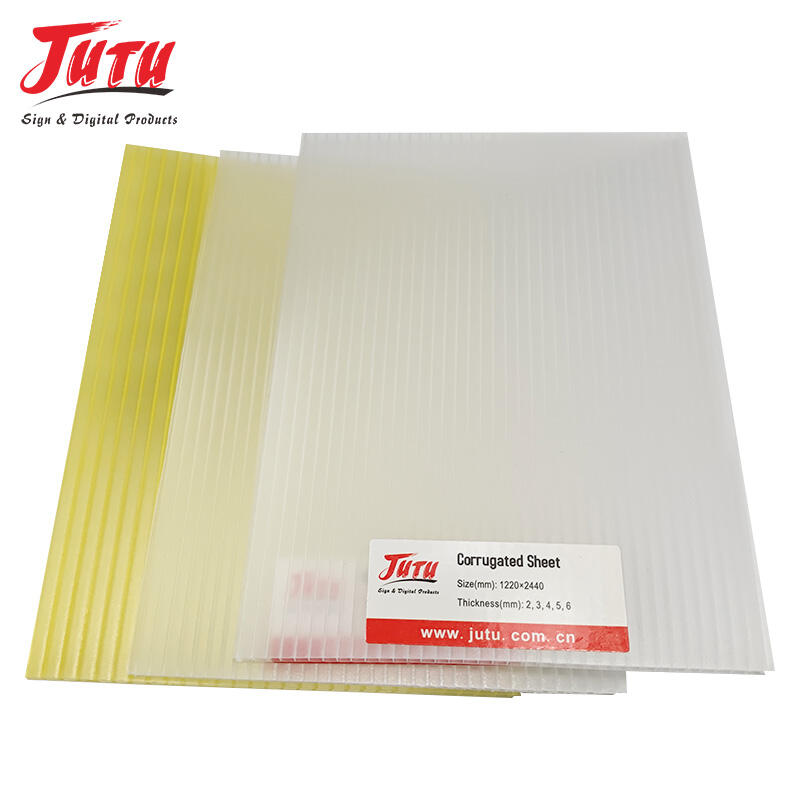

pp hollow corrugated sheet

PP hollow corrugated sheet represents a revolutionary advancement in lightweight construction materials, engineered from high-quality polypropylene to deliver exceptional performance across diverse industrial applications. This innovative material features a distinctive hollow flute structure that creates superior strength-to-weight ratios while maintaining remarkable durability. The corrugated design incorporates parallel channels running through the sheet's core, providing enhanced structural integrity without compromising flexibility. Manufacturing processes utilize advanced extrusion technology to ensure consistent wall thickness and precise dimensional accuracy throughout each pp hollow corrugated sheet. The material exhibits outstanding chemical resistance, making it suitable for harsh environmental conditions and exposure to various substances. Key technological features include excellent impact resistance, moisture barrier properties, and thermal insulation capabilities that surpass traditional solid plastic sheets. The hollow core design significantly reduces material weight while maintaining structural performance, resulting in cost-effective transportation and installation benefits. PP hollow corrugated sheet demonstrates remarkable versatility in temperature ranges, maintaining stability from -20°C to 120°C without degradation. Primary applications span packaging industries, construction sectors, automotive components, and signage solutions where lightweight yet robust materials are essential. The sheets can be easily fabricated using standard tools, allowing for cutting, drilling, and joining operations without specialized equipment. Surface treatments enable excellent printability for graphic applications, while the smooth finish resists dirt accumulation and simplifies cleaning procedures. Environmental benefits include full recyclability and reduced carbon footprint during production compared to alternative materials. The pp hollow corrugated sheet offers exceptional dimensional stability under varying load conditions, preventing warping or deformation during extended use periods.