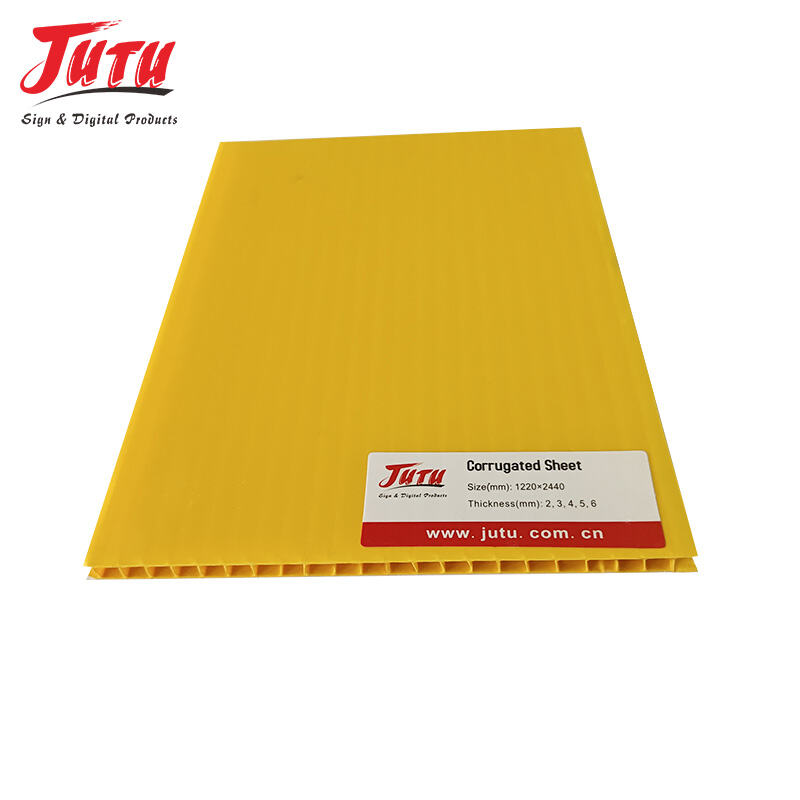

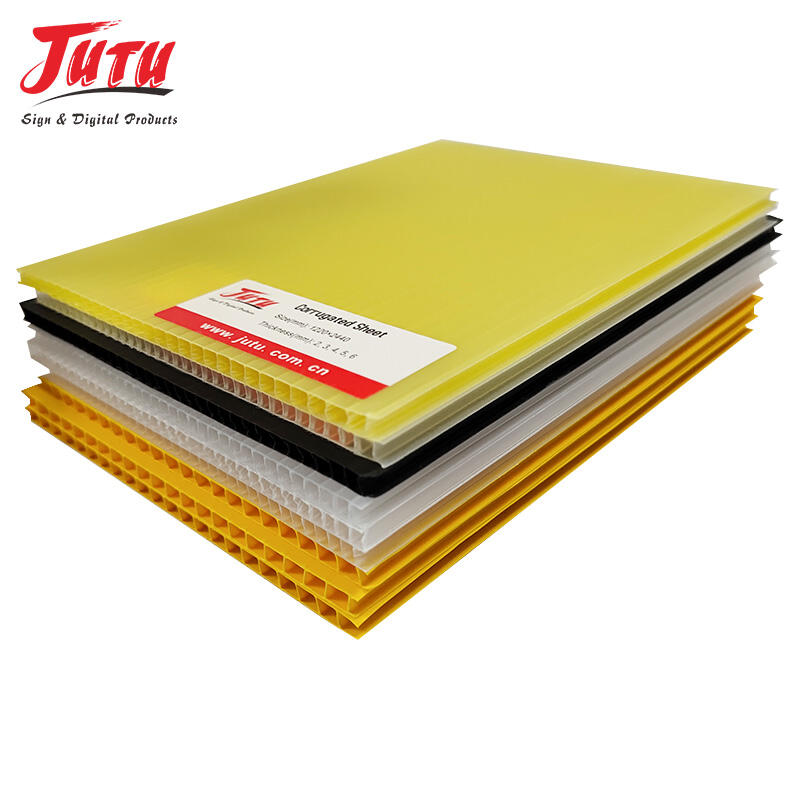

polypropylene corrugated sheet

Polypropylene corrugated sheet represents a revolutionary packaging and construction material that combines exceptional durability with remarkable versatility. This innovative thermoplastic solution consists of two flat polypropylene surfaces connected by vertical ribs, creating a hollow fluted structure that delivers outstanding strength-to-weight ratios. The polypropylene corrugated sheet manufacturing process involves advanced extrusion technology that ensures consistent wall thickness and optimal structural integrity throughout each panel. These sheets exhibit superior chemical resistance, making them ideal for environments where exposure to acids, bases, and various solvents occurs regularly. The technological features of polypropylene corrugated sheet include excellent impact resistance, maintaining structural integrity even under significant stress conditions. Temperature stability ranges from -20°C to +120°C, allowing applications across diverse climate zones and industrial settings. The material's low moisture absorption prevents warping and dimensional changes, ensuring long-term performance reliability. Polypropylene corrugated sheet applications span multiple industries, including packaging, automotive components, construction signage, and protective barriers. In packaging applications, these sheets provide exceptional protection for fragile items during shipping and storage. The automotive industry utilizes polypropylene corrugated sheet for interior panels, trunk organizers, and protective covers due to its lightweight properties and crash energy absorption capabilities. Construction professionals appreciate the material's weather resistance for temporary structures, hoarding panels, and roofing applications. The sheets can be easily cut, folded, and joined using standard tools, enabling rapid fabrication and installation. Environmental considerations make polypropylene corrugated sheet an attractive choice, as the material is fully recyclable and produces minimal waste during manufacturing. The non-toxic nature ensures safe handling without special protective equipment, while the smooth surface facilitates easy cleaning and maintenance. Print compatibility allows for high-quality graphics and branding applications, making these sheets valuable for marketing displays and promotional materials.