foam core poster board with paper backing manufacturer

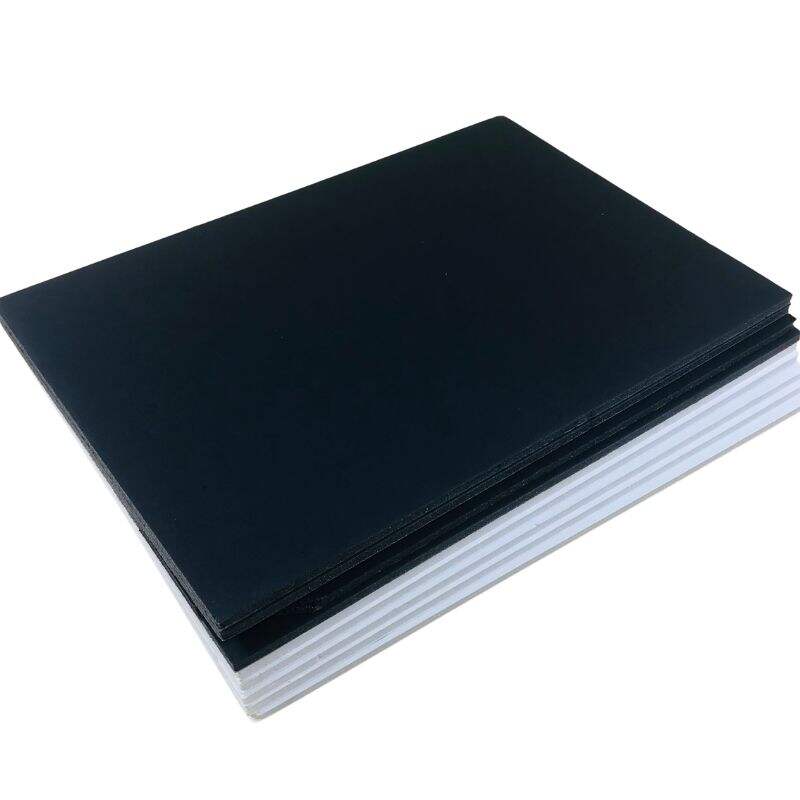

A foam core poster board with paper backing manufacturer represents a specialized production facility that creates lightweight, versatile display materials essential for professional presentations, educational environments, and creative projects. These manufacturers utilize advanced production techniques to combine expanded polystyrene foam cores with high-quality paper backing materials, resulting in rigid yet lightweight boards that offer exceptional stability and printability. The foam core poster board with paper backing manufacturer typically operates sophisticated lamination equipment that precisely bonds paper surfaces to foam centers under controlled temperature and pressure conditions. This manufacturing process ensures consistent thickness, smooth surfaces, and reliable adhesion between layers. The primary function of these manufacturers involves producing boards that maintain structural integrity while remaining easy to cut, mount, and display. Modern foam core poster board with paper backing manufacturer facilities incorporate quality control systems that monitor dimensional accuracy, surface smoothness, and color consistency throughout production runs. These manufacturers serve diverse markets including architectural firms, educational institutions, retail displays, photography studios, and artistic communities. The technological features employed by a foam core poster board with paper backing manufacturer include precision cutting systems, automated lamination processes, and environmental controls that maintain optimal humidity and temperature levels during production. Many manufacturers also offer customization services, allowing clients to specify dimensions, paper weights, and foam densities according to specific application requirements. The applications for products from a foam core poster board with paper backing manufacturer span numerous industries, from temporary signage and trade show displays to architectural models and school projects. These manufacturers must maintain strict quality standards to ensure their products meet industry specifications for flatness, edge quality, and surface uniformity, making them reliable partners for businesses requiring consistent display materials.