Hervorragende Materialeigenschaften und Leistungsvorteile

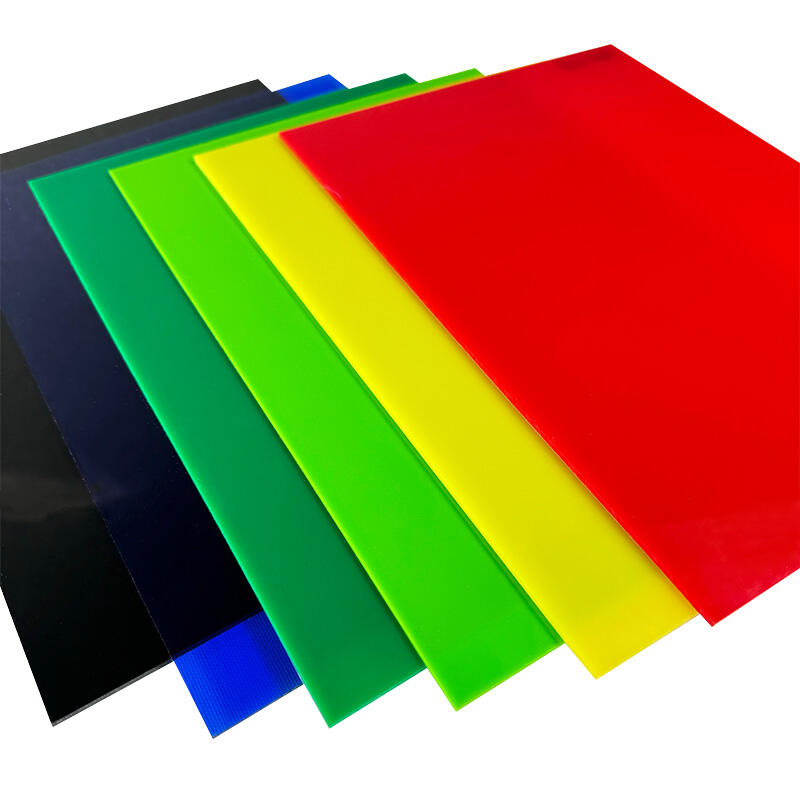

Die außergewöhnlichen physikalischen und optischen Eigenschaften von Produkten namhafter Hersteller von Qualitäts-Perspex-Plexiglas bieten Leistungsvorteile, die in zahlreichen Anwendungen deutlich über denen alternativer Materialien liegen. Die optische Klarheit stellt möglicherweise das markanteste Merkmal dar, wobei hochwertiges Perspex-Plexiglas Lichtdurchlässigkeitsraten von über 92 Prozent erreicht und dabei eine nahezu verziehungslose Sichtqualität beibehält, die mit feinstem optischem Glas konkurrieren kann. Die Schlagzähigkeit von Perspex-Plexiglas-Produkten aus renommierten Herstellerquellen bietet Sicherheitsreserven, die besonders in öffentlichen Bereichen, im Transportwesen und in Umgebungen, in denen die menschliche Sicherheit oberste Priorität hat, von großem Wert sind. Widerstandsfähigkeit gegenüber Witterungseinflüssen ermöglicht es Perspex-Plexiglas-Materialien, ihr Erscheinungsbild und ihre Leistungsmerkmale über Jahrzehnte hinweg bei Belastung durch ultraviolette Strahlung, Temperaturschwankungen und Niederschläge zu bewahren, ohne dass die bei minderwertigen Kunststoffen übliche Alterung eintritt. Die chemische Inertheit von Perspex-Plexiglas macht es für Anwendungen geeignet, bei denen Reinigungschemikalien, technische Lösungsmittel oder korrosive Umgebungen vorliegen, in denen metallische oder gläserne Alternativen beschädigt oder kontaminiert würden. Thermische Stabilität ermöglicht es Perspex-Plexiglas-Produkten, zuverlässig über einen Temperaturbereich von unter Null bis zu erhöhten Betriebstemperaturen hinweg zu funktionieren, ohne dass strukturelle Integrität oder optische Eigenschaften beeinträchtigt werden. Die geringe Gewichtsklasse von Perspex-Plexiglas, typischerweise die Hälfte des Gewichts vergleichbarer Glastafeln, reduziert die Anforderungen an die Tragkonstruktion und vereinfacht die Montage, während gleichzeitig ein hervorragendes Verhältnis von Festigkeit zu Gewicht beibehalten wird. Die ausgezeichnete Bearbeitbarkeit erlaubt Modifikationen vor Ort mit herkömmlichen Werkzeugen der Holz- und Metallbearbeitung und bietet dadurch eine Installationsflexibilität, die mit spröden Materialien wie Glas nicht möglich ist. Die elektrische Isolierfähigkeit von Perspex-Plexiglas macht es ideal für Anwendungen, die Durchschlagsfestigkeit und elektrische Sicherheit erfordern, insbesondere bei Gehäusen für elektronische Geräte und in Hochspannungsumgebungen. Langfristige Formstabilität gewährleistet, dass Produkte von Perspex-Plexiglas-Herstellern ihre ursprünglichen Spezifikationen über lange Nutzungsdauern hinweg beibehalten, wodurch Bedenken hinsichtlich Verzug, Schrumpfung oder Ausdehnung, die die Leistung oder Ästhetik beeinträchtigen könnten, entfallen.