pp corrugated sheet supplier

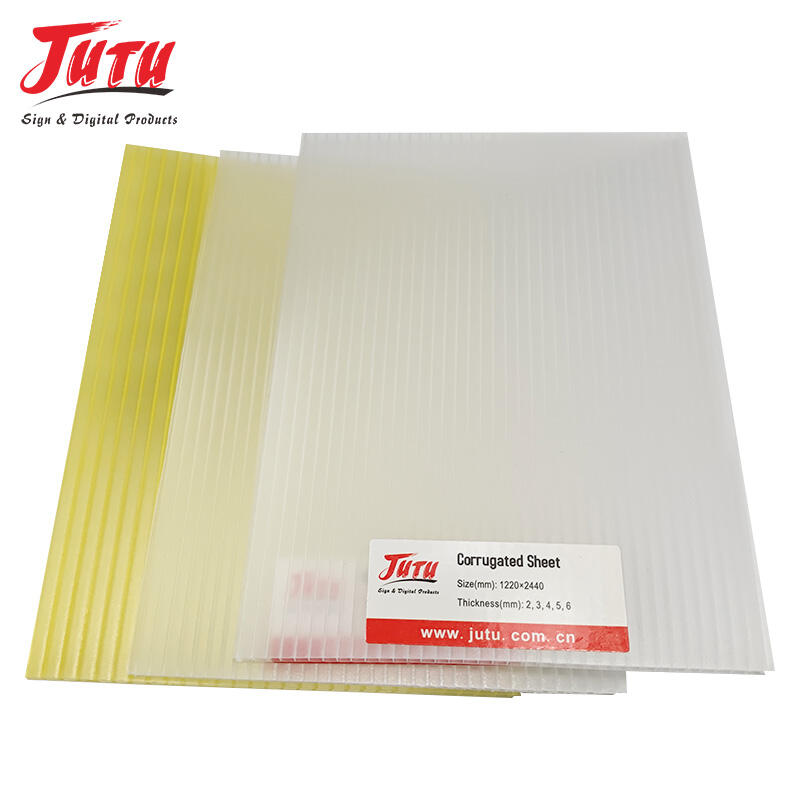

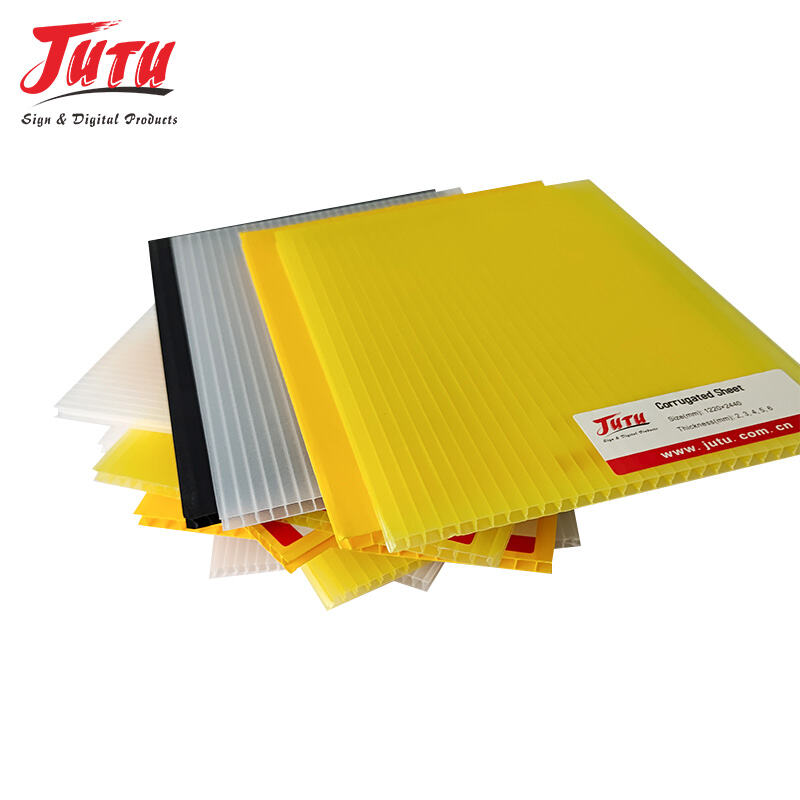

A pp corrugated sheet supplier plays a crucial role in providing high-quality polypropylene corrugated sheets that serve diverse industrial and commercial applications. These specialized manufacturers focus on producing lightweight yet durable plastic sheets featuring a unique corrugated structure that combines strength with flexibility. The main function of a pp corrugated sheet supplier involves manufacturing, distributing, and supporting customers with versatile plastic sheeting solutions that meet specific requirements across multiple industries. The technological features of modern pp corrugated sheet supplier operations include advanced extrusion processes that create consistent wall thickness and optimal flute formation. These suppliers utilize state-of-the-art manufacturing equipment to produce sheets with precise dimensions, ensuring uniform quality and performance characteristics. The corrugated design incorporates hollow channels that provide excellent strength-to-weight ratios while maintaining cost-effectiveness. Many pp corrugated sheet supplier facilities employ multi-layer extrusion technology, allowing for customized properties such as enhanced UV resistance, antistatic properties, or specific color requirements. Applications for products from a pp corrugated sheet supplier span numerous sectors including packaging, construction, automotive, agriculture, and signage industries. In packaging applications, these sheets serve as protective dividers, returnable containers, and shipping boxes that withstand repeated use. Construction projects utilize these materials for temporary protection, hoarding panels, and lightweight structural components. The agricultural sector benefits from greenhouse glazing, plant protection covers, and storage solutions. Automotive manufacturers incorporate these sheets for interior panels, protective covers, and lightweight components. A reliable pp corrugated sheet supplier typically offers various thicknesses, colors, and surface treatments to accommodate specific project requirements, ensuring optimal performance in each application while maintaining competitive pricing and consistent supply chain management.