Többféle testreszabási lehetőség és alkalmazási rugalmasság

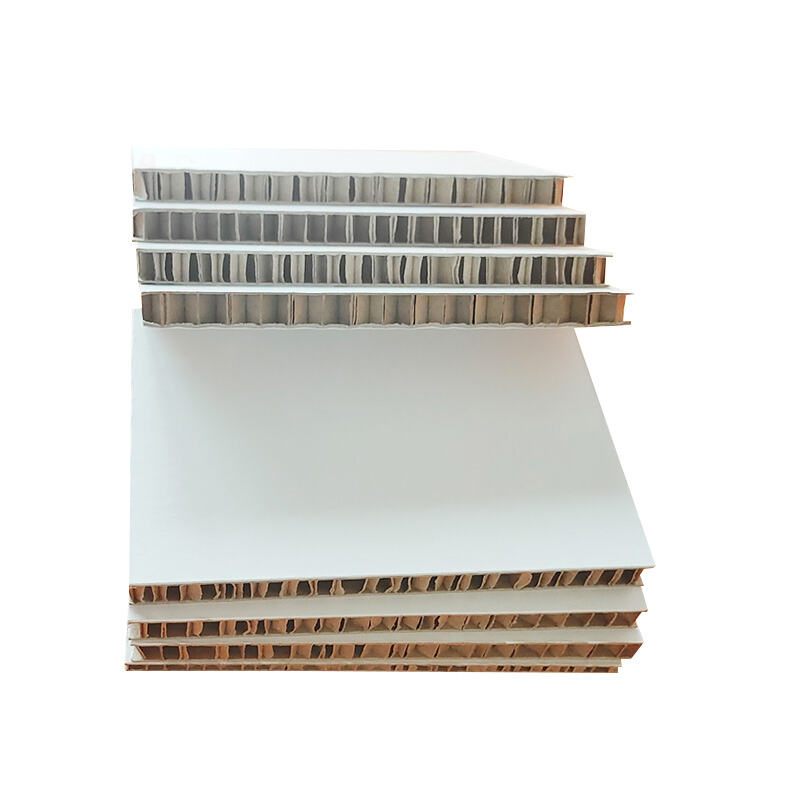

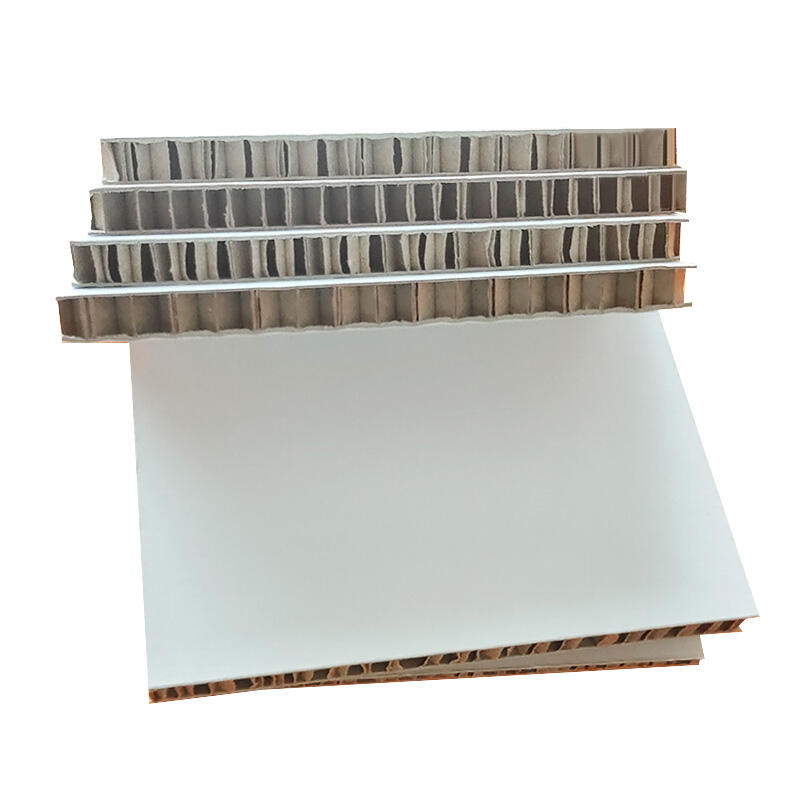

A méhsejtes hullámpapír kivételes sokoldalúsága kiterjedt testreszabási lehetőségeket biztosít, amelyek különböző iparágakban felmerülő változatos alkalmazási igényeket elégítenek ki, miközben folyamatosan magas minőségi és teljesítményszintet tart fenn. Ez az alkalmazkodóképesség a rugalmas gyártási folyamatokból ered, amelyek pontos ellenőrzést tesznek lehetővé a vastagság, sűrűség, cellaméret és fedőréteg anyagai tekintetében, így speciális védelmi és szerkezeti igényekre szabott megoldások hozhatók létre. Az egyedi méretezési lehetőségek csökkentik a hulladékot, és optimalizálják a csomagolási hatékonyságot, mivel minden darab pontosan a szükséges méretre készülhet, nem pedig arra kényszerítve a termékeket, hogy meglévő, szabványos csomagolási formátumokba illeszkedjenek. Az anyag különféle nyomtatási technikákat támogat, beleértve a digitális nyomtatást, fólianyomtatást és flexográfiai nyomtatást, lehetővé téve a vállalkozások számára, hogy közvetlenül a védőcsomagolás felületére helyezzék el márkaelemeket, kezelési utasításokat és termékinformációkat. A felületkezelési lehetőségek tovább bővítik az alkalmazási területeket: elérhetők olyan bevonatok, amelyek növelik a nedvességállóságot, javítják a nyomtathatóságot, vagy antistatikus tulajdonságot biztosítanak érzékeny elektronikus alkatrészekhez. A laminálási lehetőségek különböző fedőréteg-anyagok – például kraftpapír, fehér fedőlapok vagy speciális fóliák – integrálását teszik lehetővé, hogy megfeleljenek adott esztétikai vagy funkcionális követelményeknek. A méhsejtes hullámpapír bonyolult alakokra és konfigurációkra is kivágható, támogatva az összetett csomagolási terveket, amelyek pontosan illeszkednek a termék kontúrjaihoz, miközben megőrzik a szerkezeti integritást. A szerelési módszerek egyszerű hajtogatási műveletektől kezdve kifinomult, egymásba kapcsolódó rendszerekig terjednek, amelyek biztonságos, segédberendezés nélküli csomagolási megoldásokat hoznak létre, alkalmasak nagy sorozatú gyártási környezetekre. A fedőlapok kiválasztásával lehetséges a szín testreszabása, így a márkaegyütthatóság és a vizuális hatásfokozás érhető el anélkül, hogy a védőhatás romlana vagy jelentős költségnövekedés lépne fel. A perforációs lehetőségek szabályozott szakíthatóságot és könnyű hozzáférést biztosítanak, miközben a csomagolás általános integritása normál kezelés mellett megmarad. Az anyag jól fogadja az ragasztókat, szalagokat és mechanikus rögzítőelemeket, többféle szerelési lehetőséget kínálva különböző gyártási folyamatokhoz és automatizálási igényekhez. A feldolgozó berendezések kompatibilitása biztosítja a zökkenőmentes integrációt a meglévő csomagolóvonalakba minimális módosítási igény mellett, támogatva a hatékony bevezetést különböző gyártási környezetekben és termelési léptékekben, miközben megőrzi a méhsejtes hullámpapír kiváló védőtulajdonságait, amelyek miatt ez az anyag kiemelkedő csomagolási megoldás.