Polyvalence remarquable du design et attrait esthétique

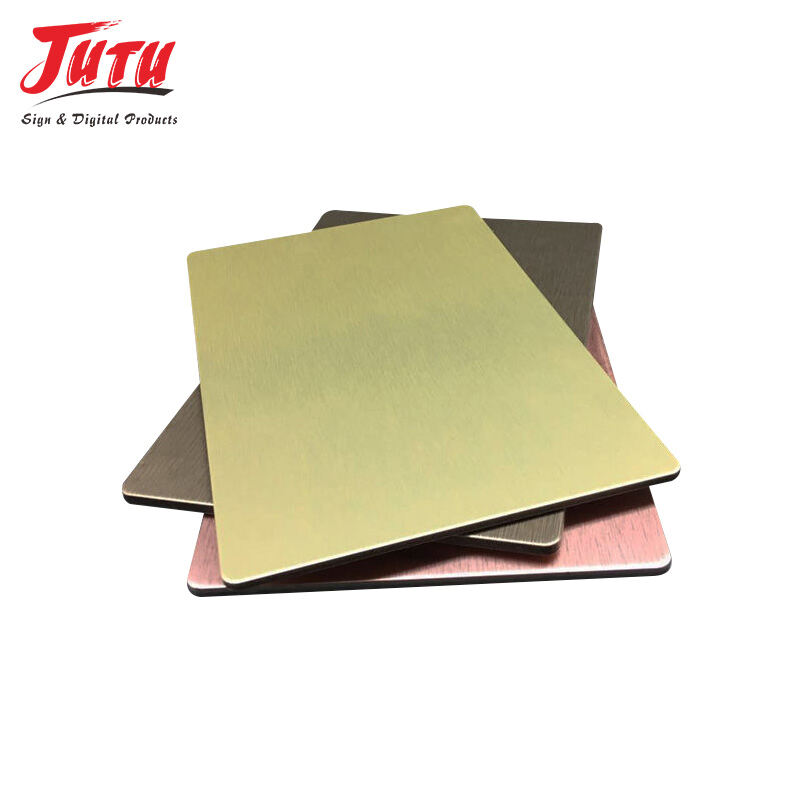

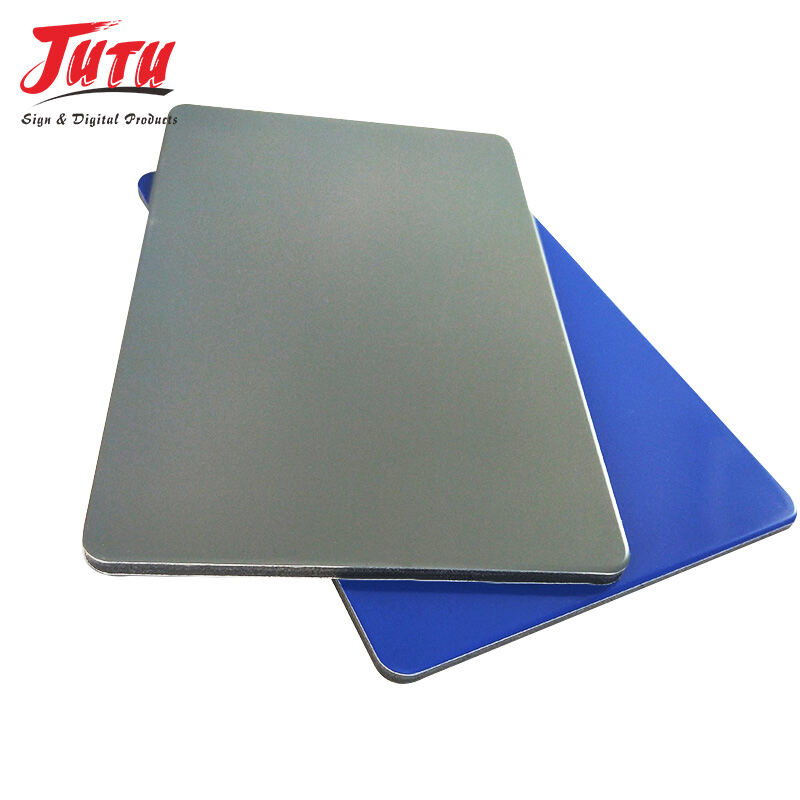

Le panneau composite en aluminium marbré offre une polyvalence de conception et un attrait esthétique sans précédent, permettant aux architectes et designers de créer des effets visuels spectaculaires tout en conservant une fonctionnalité pratique et une rentabilité. Ce système de matériau innovant reproduit l'apparence luxueuse du marbre naturel haut de gamme avec une précision photoréaliste, grâce à des technologies d'impression numérique avancées qui capturent chaque variation subtile, motif de veine et nuance de couleur présents dans les variétés de marbre les plus prisées au monde. Le procédé de fabrication permet une correspondance personnalisée des couleurs et la reproduction de motifs, permettant aux concepteurs d'obtenir des résultats esthétiques cohérents sur de grandes surfaces, sans les variations naturelles ni les limitations d'approvisionnement liées aux matériaux en pierre extraite. Les options de finition de surface incluent des traitements polis, mats, brossés et texturés qui renforcent la profondeur visuelle et les qualités tactiles des systèmes de panneaux composites en aluminium marbré. La flexibilité intrinsèque du matériau supporte des formes architecturales complexes, notamment des surfaces courbes, des géométries angulaires et des transitions continues, qui seraient techniquement impossibles ou prohibitivement coûteuses avec des matériaux en pierre naturelle. Les capacités de fabrication comprennent des opérations de découpe, de fraisage et de façonnage de précision, permettant des détails complexes, des profilés sur mesure et des systèmes de fixation intégrés qui simplifient l'installation tout en conservant une apparence soignée et professionnelle. La stabilité des couleurs constitue un avantage significatif par rapport aux matériaux naturels, car le panneau composite en aluminium marbré conserve une apparence constante tout au long de sa durée de vie, sans taches imprévisibles, altérations dues aux intempéries ou développement de patine pouvant affecter les installations en pierre naturelle. Les caractéristiques légères du matériau permettent des porte-à-faux impressionnants, des systèmes suspendus et d'autres éléments architecturaux qui nécessiteraient un soutien structurel important avec des matériaux traditionnels. Les options de dimensions de panneaux s'adaptent aussi bien aux grandes surfaces continues qu'aux applications décoratives détaillées, offrant une grande souplesse pour diverses échelles de projet et exigences de conception. La surface du panneau composite en aluminium marbré peut recevoir des traitements supplémentaires, notamment des finitions métalliques, des graphismes personnalisés et des systèmes d'éclairage intégrés, élargissant ainsi les possibilités créatives au-delà des limites des matériaux traditionnels. Les processus de contrôle qualité garantissent une correspondance parfaite des couleurs entre les panneaux et des caractéristiques de surface homogènes, éliminant ainsi les difficultés de tri et de sélection fréquentes dans les projets utilisant de la pierre naturelle. Des technologies de revêtement avancées protègent les qualités esthétiques tout en offrant des avantages fonctionnels supplémentaires, tels que des propriétés autonettoyantes et des traitements antimicrobiens de surface.