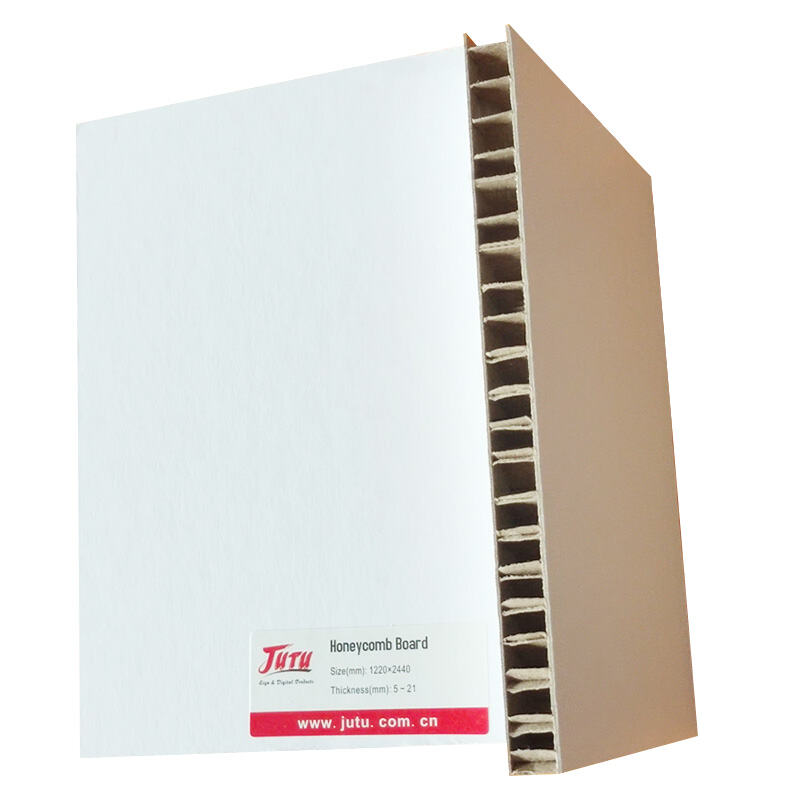

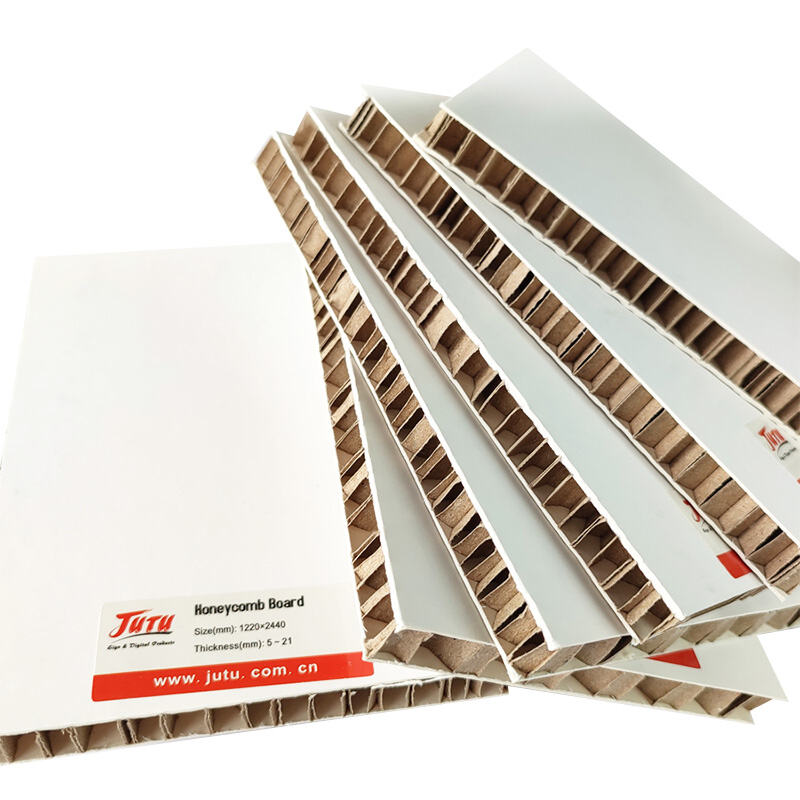

panneaux muraux en aluminium à base de nid d'abeille

Les panneaux muraux en nid d'abeille en aluminium représentent une avancée révolutionnaire dans la technologie moderne de la construction, alliant ingénierie légère et performances structurelles exceptionnelles. Ces panneaux innovants intègrent une structure centrale unique en forme de nid d'abeille, prise en sandwich entre deux feuilles d'aluminium, créant ainsi un matériau composite offrant d'excellents rapports résistance-poids. La configuration hexagonale des alvéoles du noyau reproduit le design structurel le plus efficace trouvé dans la nature, assurant une rigidité maximale tout en minimisant l'utilisation de matière. Cette méthode de construction sophistiquée transforme les panneaux muraux en nid d'abeille en solutions polyvalentes adaptées aux applications intérieures comme extérieures. Le procédé de fabrication consiste à coller des parements en aluminium sur un noyau en nid d'abeille en aluminium expansé à l'aide d'adhésifs haute performance, produisant des panneaux qui conservent leur stabilité dimensionnelle dans diverses conditions environnementales. Ces panneaux excellent par leurs propriétés d'isolation thermique, d'atténuation acoustique et de résistance au feu, ce qui les rend idéaux pour les bâtiments commerciaux, les constructions résidentielles et les installations industrielles. Leur conception modulaire facilite une installation rapide et réduit considérablement les délais de construction. Leur nature non combustible et leurs faibles besoins en entretien les rendent particulièrement précieux pour les immeubles de grande hauteur et les structures exigeant des normes de sécurité renforcées. Les panneaux peuvent être personnalisés avec différentes finitions de surface, couleurs et textures afin de répondre à des exigences architecturales spécifiques. Des technologies de revêtement avancées protègent les panneaux muraux en nid d'abeille contre la corrosion, les rayons UV et l'usure climatique, garantissant durabilité et attrait esthétique à long terme. Ces panneaux trouvent un large éventail d'applications dans les systèmes de mur-rideau, les bardages de façade, les cloisons, les plafonds suspendus et les éléments architecturaux décoratifs. L'influence de l'industrie aérospatiale sur leur développement a permis de concevoir des panneaux muraux en nid d'abeille alliant technologie de pointe et solutions pratiques en construction, offrant aux architectes et constructeurs une flexibilité de conception inégalée tout en préservant intégrité structurelle et excellence des performances.