Aussergewöhnliche Designflexibilität und ästhetische Anziehungskraft

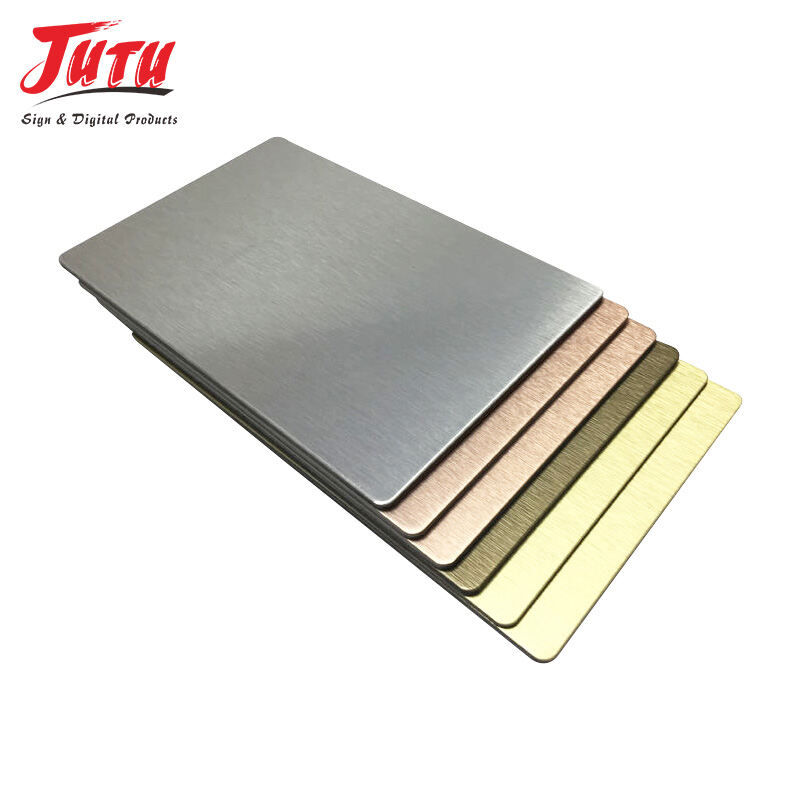

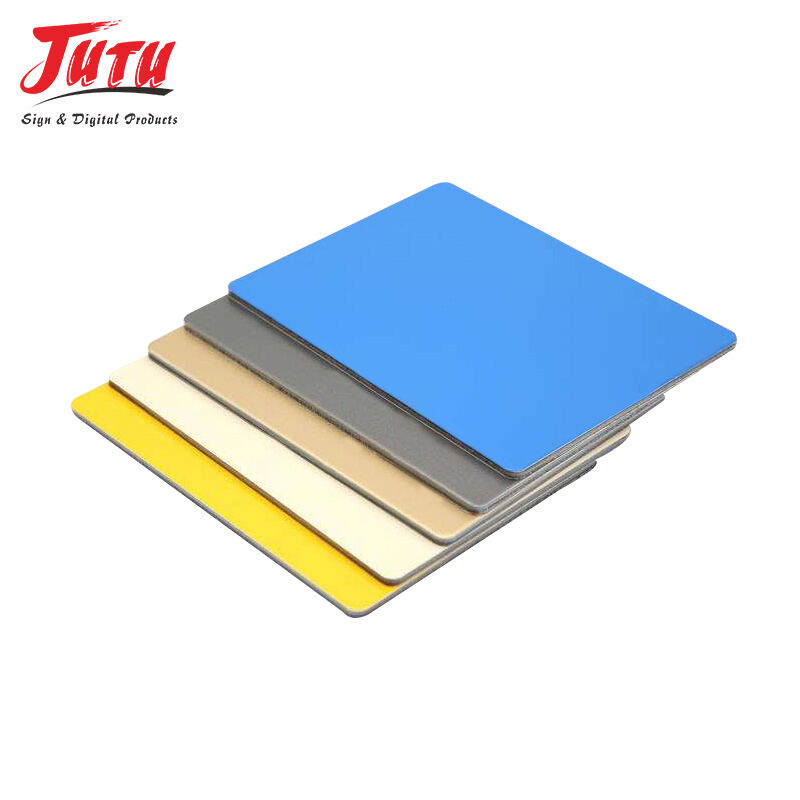

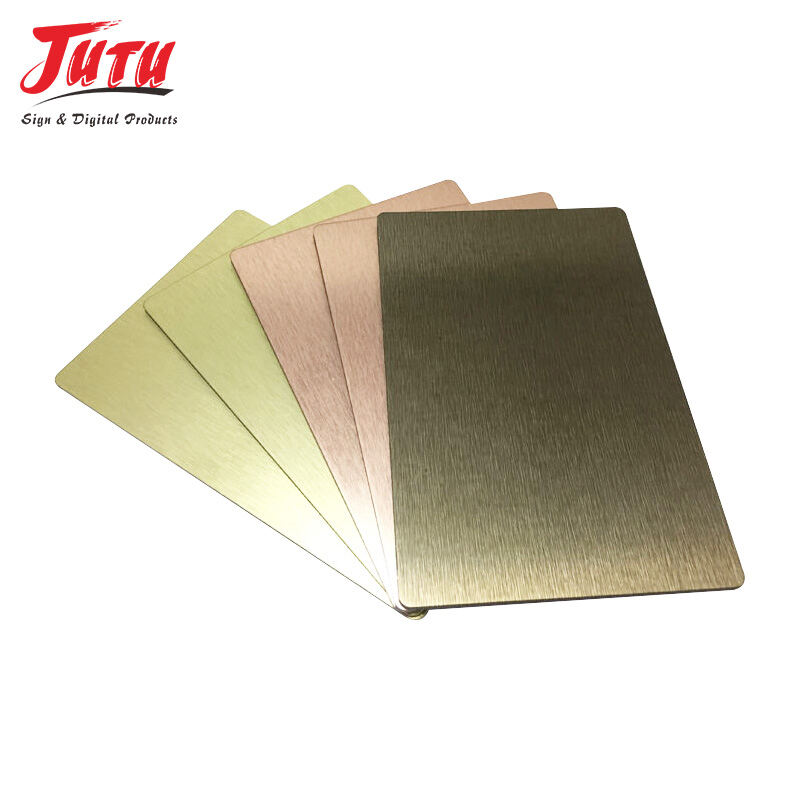

Die ACM-Metallplatte bietet eine unübertroffene Gestaltungsfreiheit, die es Architekten und Designern ermöglicht, ihre kreativen Visionen umzusetzen, ohne dabei praktische Bauüberlegungen außer Acht zu lassen. Durch die Umformbarkeit können diese Platten zu komplexen Kurven, Winkeln und dreidimensionalen Formen geformt werden, die auffällige architektonische Merkmale und dynamische Gebäudefassaden schaffen. Die Möglichkeit der exakten Farbanpassung stellt sicher, dass projektspezifische ästhetische Anforderungen präzise erfüllt werden, wobei nahezu unbegrenzte Farboptionen durch fortschrittliche Beschichtungstechnologien verfügbar sind. Oberflächenstruktur-Varianten bieten zusätzliche Gestaltungsmöglichkeiten – von glatten, modernen Oberflächen bis hin zu strukturierten Flächen, die natürliche Materialien wie Holzmaserung oder Steinoberflächen nachahmen. Die ACM-Metallplatte kann mit Perforationen, Ausschnitten oder profilierten Kanten gefertigt werden, um einzigartige visuelle Effekte sowie funktionale Elemente wie Lüftungsgitter oder dekorative Bauteile zu schaffen. Modulare Plattensysteme ermöglichen eine schnelle Montage, während die gestalterische Kontinuität über große Gebäudeauflächen erhalten bleibt. Die Integration mit anderen Baumaterialien erlaubt es Planern, ACM-Metallplatten mit Glas-, Beton-, Holz- oder Steinelementen in harmonischen architektonischen Kompositionen zu kombinieren. Die Abmessungsoptionen reichen von kleinen Akzentplatten bis hin zu Großformatplatten, die sichtbare Fugen minimieren und ein nahtloses Erscheinungsbild erzeugen. Die geringe Gewichtsklasse der ACM-Metallplatten ermöglicht die Installation an Konstruktionen, die keine schweren Bekleidungslasten tragen können, und erweitert so die Gestaltungsmöglichkeiten bei Sanierungsprojekten und leichten Bausystemen. Befestigungssysteme für die Platten unterstützen verschiedene Montageverfahren – von der herkömmlichen Schraubbefestigung bis hin zu anspruchsvollen Strukturglaser-Techniken, die saubere, unterbrechungsfreie Oberflächen erzeugen. Spezielle Oberflächenoptionen umfassen metallische Effekte, Holzmaserungen und Steinoberflächen, die das Aussehen natürlicher Materialien bei reduzierten Kosten und geringerem Gewicht bieten. Digitale Drucktechnologien ermöglichen die Anbringung von individuellen Grafiken, Mustern oder Bildern auf den Oberflächen der ACM-Metallplatten und schaffen so einzigartige Branding-Möglichkeiten oder künstlerische Ausdrucksformen. Qualitätskontrollmaßnahmen gewährleisten, dass Sonderfarben und Oberflächen exakt den genehmigten Musterproben entsprechen, Überraschungen bei der Montage verhindern und die Gestaltungstreue über den gesamten Projektverlauf hinweg sicherstellen.