What Are Aluminum Composite Plates?

Composition and Manufacturing Process

Aluminum composite panels, or ACPs for short, basically consist of two thin sheets of aluminum wrapped around something else in the middle. What goes between those aluminum skins varies quite a bit actually - sometimes it's just plain old polyethylene plastic, other times manufacturers might throw in some minerals or fire retardants too. This sandwich construction makes them surprisingly light while still holding up pretty well against wear and tear. Making these panels involves what's called continuous lamination, where they press everything together at just the right temperature and pressure so it all sticks properly without any gaps. Most factories run pretty strict quality checks throughout the whole production line because nobody wants their building facades falling apart after a few years. The end result needs to pass all sorts of tests for how strong it is, whether it catches fire easily, and if it will hold up against whatever weather conditions Mother Nature throws at it.

Types of Aluminum Composite Plates

Aluminum composite panels come in all sorts of varieties depending on what someone needs them for. Most folks will run across standard, fire rated, or antibacterial versions when shopping around. Standard ACPs get used everywhere from building exteriors to signs because they hold up well and look good too. Fire rated panels are another story entirely though. Building codes require these special ones in certain applications where fire safety matters most. They pass those tough tests and help buildings resist flames better than regular panels can. We're also seeing more companies jump on board with making eco friendly alternatives lately. Some manufacturers have started incorporating recycled materials or cutting down waste during production. Green builders love these options since they fit right into LEED certified projects without compromising performance requirements.

Key Benefits of Aluminum Composite Plates

Lightweight and Durable Construction

Aluminum composite plates, or ACPs as they're often called, have this great combination of being light but still really tough. Compared to regular aluminum or steel sheets, they weigh about half as much, which means less strain on transportation costs and easier installation on site. For builders working on big projects, cutting down on material weight translates into real savings across the board. What's interesting though is that despite their lightness, these panels hold up surprisingly well. Most last around 20 years if kept in good condition, sometimes even longer. They just don't bend easily, withstand impacts pretty well, and resist rusting out in the elements. That's why we see them everywhere now - from towering skyscrapers needing exterior cladding to simple street signs that need to stand up to weather. The whole package makes life simpler for everyone involved, especially since nobody wants to deal with replacement costs every few years.

Fire Resistance and Safety Compliance

Adding fire resistance to building components makes all the difference when it comes to occupant safety, which is why so many aluminum composite panels (ACPs) now come with fire protection built right in. These panels with fire rated cores actually pass those tough building codes that cities require before giving permission to construct anything new. Real world tests show buildings equipped with these special ACPs hold up much better during fires, keeping people safe inside while also protecting valuable assets outside. Architects know full well that following fire safety regulations isn't just about avoiding fines either. Clients love seeing these safety features listed on spec sheets because they want assurance their investment won't go up in smoke literally or figuratively speaking. That's why we see more and more builders specifying these fire resistant materials across commercial projects today.

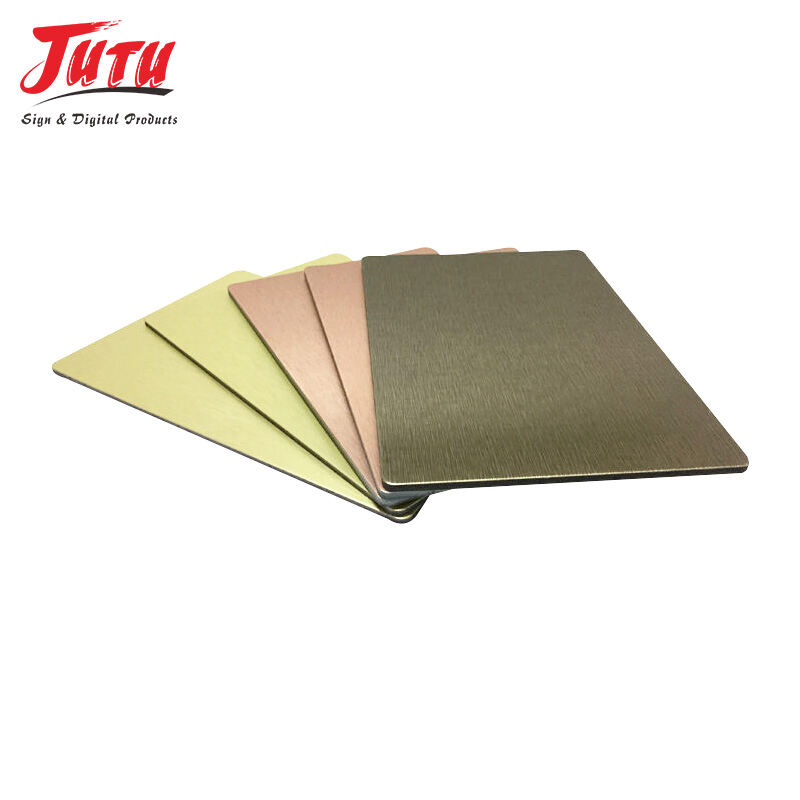

Aesthetic Versatility and Design Flexibility

Aluminum composite panels have become really popular among designers because they offer so much creative freedom. These materials come in countless colors and surface treatments, letting architects play around with different styles ranging from eye-catching geometric designs to more understated traditional appearances. The fact that these panels can be cut and formed relatively easily makes them adaptable to just about any building style, whether someone wants something cutting edge or something more classic looking. Plus, good quality finishes stand up well against fading over time, which keeps buildings looking fresh for years even when exposed to harsh weather conditions. For this reason, many construction professionals choose ACPs when working on projects where appearance matters as much as performance does, proving once again that beautiful buildings don't have to sacrifice practicality.

Applications in Modern Construction and Design

Exterior Cladding and Facade Systems

Aluminum Composite Plates, or ACPs as they're commonly called, have become really popular among architects when it comes to outside cladding on modern buildings. The main reasons? They're super light weight and work great for all sorts of different applications. These plates actually help buildings save energy because they act like good insulators. Most architects love working with ACPs since they offer so many ways to customize the look. Buildings with ACP facades tend to stand out visually while still holding up against tough weather conditions. There are plenty of real world examples where this material has been successfully used in tall buildings. Take those big city skylines for instance many of the tallest structures incorporate aluminum composite plates not just for their sleek appearance but also because they maintain strong structural properties even though they look so thin and modern.

Interior Design and Decorative Solutions

ACP sheets show up all over interior design these days, from fancy wall panels and ceiling treatments to custom art installations in homes and offices alike. The fact that they're so simple to clean makes them a real asset in high traffic areas like clinics and school buildings where dirt and grime tend to accumulate fast. When designers incorporate ACP into their plans, they get better sound control and improved temperature regulation while adding that contemporary look everyone wants nowadays. Take hospital hallways for instance. Those smooth, shiny panels do double duty by maintaining a clinical feel without looking cold or impersonal. That's why many architects keep coming back to ACP when creating spaces that need both function and style.

Specialized Industrial and Commercial Uses

ACP panels are showing up everywhere in factories these days for things like signs, machine covers, and dividing walls because they just hold up so well and are easy to work with. We see them in places like information kiosks, those fancy food displays at supermarkets, and all sorts of retail spaces where something needs to last but still look good. Industry numbers suggest that specialty markets are adopting ACPs faster than ever before, probably because they actually perform better than many alternatives. Businesses love how these panels let them make colorful signs that stick around for years or set up temporary stores that can be moved around as needed. That flexibility explains why more manufacturers and shop owners keep turning to ACP materials whenever they need something durable but also visually appealing for their operations.

Installation and Maintenance Best Practices

Essential Tools and Techniques for Installation

Installing Aluminum Composite Panels (ACP) needs careful attention to detail and following certain methods if we want them to last and perform well. Getting the right equipment matters a lot too special saws for cuts and good quality drills for attaching everything properly. The right tools make all the difference when keeping those panels intact and getting them to fit together without gaps. Most importantly, always check what the manufacturer says about how to install their product. Following those directions gives a much better looking result and makes sure the panels will stand up to wear and tear over time. Proper installation prevents problems down the road like warped panels or things not lining up correctly which ruins both function and appearance. Don't forget protective gear either gloves, goggles, maybe even ear protection depending on what's going on at the worksite. And before starting any major project, look into local building regulations for ACP installations. This saves headaches later and confirms everything complies with safety requirements and quality expectations in the area.

Long-Term Maintenance and Care Tips

Keeping aluminum composite panels looking good requires some basic care routines. Regular cleaning stops dirt buildup which eventually causes those annoying little scratches on the surface. Cleaning matters a lot though - nobody wants to ruin the finish. Stick to gentle cleaners instead of harsh chemicals that eat away at the material. Most contractors recommend using mild soap solutions with soft cloths or sponges. Setting up a proper maintenance routine makes all the difference in how long these panels last. Check for any chips or discoloration during routine walks through the building, especially after heavy rainstorms when water might have tracked in debris. Clean spots as soon as they appear before they become permanent stains. Building managers who follow this approach find their ACP installations stay beautiful much longer than those neglected ones across town. The savings from avoiding early replacement alone justify the extra attention.

Sustainability and Environmental Impact

Recyclability and Eco-Friendly Manufacturing

Aluminum composite plates or ACPs have become popular among green building projects because they can actually be recycled multiple times. Most makers now try to work recycled aluminum into their production lines wherever possible. Recycling these materials helps cut back on waste and saves a lot of energy compared to making new aluminum from scratch. Some ACP brands even carry certifications from well known green groups, showing they follow certain environmental standards in how they're made. When builders opt for ACP solutions instead of other options, they help reduce the overall carbon footprint without compromising quality standards in construction work.

Energy Efficiency in Building Design

Aluminum composite plates have pretty good insulation qualities that make buildings more energy efficient overall. When installed properly, these panels cut down on both heating bills during winter months and air conditioning expenses in summer, making buildings cheaper to operate long term. Research shows buildings with ACP installations tend to get better energy star ratings than those without them, something that green building consultants love to highlight when pitching projects to eco-conscious clients. The push for greener buildings isn't just about saving money either. Many cities now require certain energy performance standards for new constructions, and ACPs help meet those benchmarks while still looking sharp on the outside. For architects working on commercial projects, this means they can satisfy both environmental goals and code requirements at the same time without compromising design aesthetics.

Frequently Asked Questions

-

What are aluminum composite plates made of?

Aluminum composite plates typically consist of two thin layers of aluminum enclosing a non-aluminum core, which can be made of polyethylene or mineral-based materials. -

What are the types of aluminum composite plates?

There are several types, including standard, fire-rated, and anti-bacterial versions, each designed for specific applications. -

How are aluminum composite plates installed?

Installation requires specific tools and techniques, adhering to manufacturer guidelines and local building codes to ensure optimal performance and safety. -

Are aluminum composite plates eco-friendly?

Yes, they are recyclable, and many manufacturers use recycled materials and sustainable practices to minimize environmental impact. -

How long do aluminum composite plates last?

When properly installed and maintained, ACPs typically last over 20 years.