Why Choose Acrylic Boards for Durable Displays?

Superior Durability Compared to Traditional Materials

Acrylic boards really shine when it comes to lasting power compared to old school materials such as glass and wood. Glass tends to break easily, while acrylic resists cracking and bending even under pressure. That's why so many people choose acrylic for displays that might get bumped around or exposed to rough handling. Research shows these boards can handle all sorts of weather extremes too, making them great choices whether they're going inside or outside. Most manufacturers back up their claims with solid guarantees lasting anywhere between ten and thirty years on the product life span. Combine this toughness with how long they last, no wonder so many businesses opt for acrylic whenever they need something that will stick around for years without falling apart.

Optical Clarity and Lightweight Design

What really sets acrylic apart from other materials is how clear it actually is. Acrylic lets through around 92% of visible light, which means anything displayed behind it looks brighter and stands out more clearly to people passing by. That kind of clarity makes reading text or seeing product details much easier. Plus, acrylic weighs way less than regular glass does. The difference in weight matters a lot for shipping expenses and makes setting things up on site much simpler for installers. Because it's so light, designers have more freedom to create interesting shapes and structures without worrying about structural limitations. Retail stores and advertisers love this because they can experiment with different display configurations quickly and affordably. When businesses need something that looks good while still being practical for their display needs, acrylic tends to come out on top most of the time.

Impact-Resistant Properties for Long-Term Use

Acrylic stands out not just because it's clear and light, but also thanks to how tough it is against impacts, which makes it great for lasting installations. Acrylic panels can take about ten times more force than regular glass before breaking, so they work well in busy areas or places where things need to last forever, think schools or city centers. Tests show these boards rarely shatter or develop cracks even when hit hard, saving money on repairs and replacements over time. Schools have found this especially useful since kids tend to be rough with displays. The durability factor explains why so many businesses now go for acrylic when setting up permanent exhibition stands or signage that needs to withstand daily wear and tear without constant fixing.

Manufacturing Processes of Acrylic Boards

Cell Cast vs. Extruded Acrylic: Key Differences

Knowing when to choose cell cast versus extruded acrylic makes all the difference in getting the right material for the job. With cell cast acrylic, manufacturers pour liquid resin between glass panels, creating material that has exceptional clarity and minimal internal stress points. These characteristics translate into better light transmission and longer lasting products, especially under harsh conditions. Extruded acrylic works differently. The production involves pushing molten plastic through dies in a continuous operation. While this method keeps costs down, it does leave behind minor flaws that aren't present in cell cast versions. For projects where appearance matters most or where materials will face constant stress, going with cell cast usually pays off despite the higher price tag. The decision between these options really impacts how well the finished item holds up over time and looks throughout its lifespan.

Quality Control in Acrylic Board Production

Good quality control matters a lot when making acrylic boards because nobody wants cloudy or weak materials showing up in their projects. Most manufacturers run all sorts of tests during production to catch those tiny flaws that might ruin the whole batch. They check for bubbles, color variations, thickness issues basically anything that makes the acrylic look less than perfect. Without these checks, entire shipments could end up being rejected by customers. Industry certifications like ISO standards aren't just paperwork either. Getting certified means going through real hands-on evaluations where experts actually test samples under different conditions. This proves that the company stands behind its products whether they're going into aquariums, signage displays or medical equipment.

Key Features of High-Quality Acrylic Boards

UV Resistance for Outdoor Applications

Acrylic boards with good UV protection really shine when used outside for long periods. The material is built to fight against sun damage so it keeps looking clear and colorful even after months under the weather. Lab tests show these UV resistant boards stop colors from fading away, which matters a lot for things like store signs or exhibition displays that get constant sun exposure. What makes this stuff special is that it stays attractive while lasting much longer than regular materials would. Outdoor businesses save money in the long run because they don't have to replace faded signs as often as they might with other types of plastic.

Scratch-Resistant Surface Treatments

Surface treatments that resist scratches really matter when it comes to how long acrylic displays last and how good they look over time. These coatings help fight off those little daily scrapes so the boards don't get all scuffed up and lose their nice appearance too quickly. Research shows that acrylics with this treatment hold up much better against normal wear and tear, which makes sense why so many businesses choose them as their go to material for displays that need to stand the test of time. Most manufacturers actually include some basic tips on cleaning and taking care of these surfaces right in their product manuals, helping ensure customers get the most out of their investment while keeping that professional look intact for years.

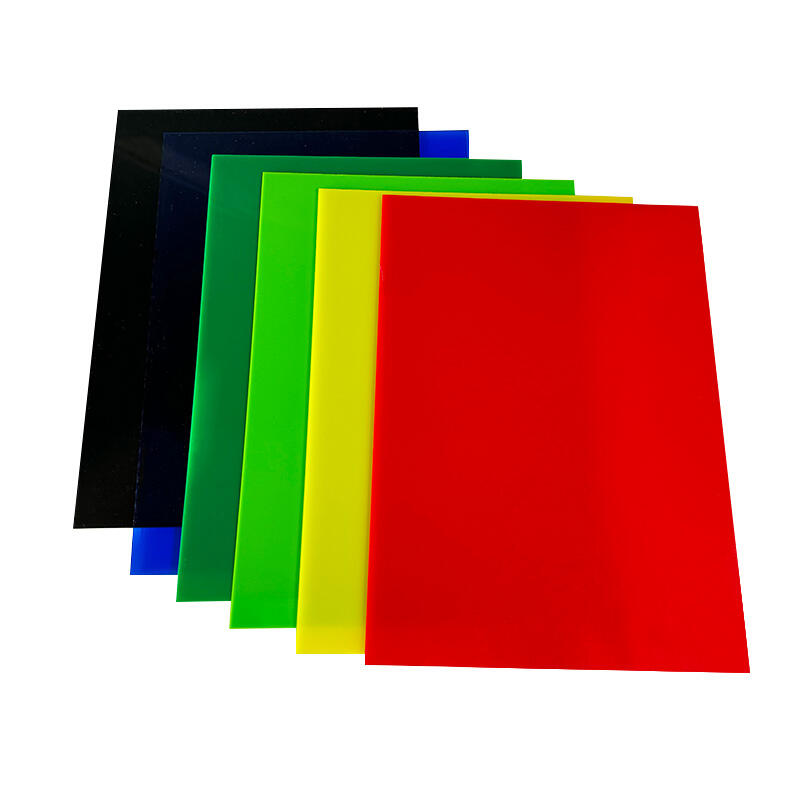

Customizable Thickness and Color Options

Manufacturers of acrylic boards provide all sorts of thicknesses and colors, so they can create products that fit what clients actually need. This means businesses can get boards that really match their brand identity, which matters a lot when making signs or promotional stuff for events. Customization makes these boards work well in lots of different areas too. We see them everywhere now from store window displays to art projects in public spaces. The fact that acrylic comes in so many forms explains why it keeps showing up in new applications across various fields. Retailers love it because it looks good and lasts long without breaking down easily.

Applications of Acrylic Boards in Modern Industries

Retail Displays and Visual Merchandising

Retail stores are turning to acrylic boards for their displays because these materials just work so well for visual merchandising. They're light enough to handle without breaking the back, yet strong enough to last through countless rearrangements. Store owners love how they can quickly modify displays when new trends hit or promotions change direction. The clear nature of acrylic gives products that extra shine that catches eyes walking past shelves. Some studies out there actually show that stores using acrylic displays tend to get more customers interacting with products directly. We've seen this happen time and again in actual store settings where sales staff report better engagement from shoppers who spend more time looking at items displayed behind acrylic rather than traditional glass or cardboard setups.

Architectural Signage and Interior Design

Acrylic boards have become really popular among architects and interior designers because they look great and can be lit up for special effects. People use them everywhere these days - from fancy store signs to cool wall panels and furniture accents. Many designers love working with acrylic for room dividers and decorative touches since it makes spaces feel bigger and brighter while still looking stylish. The numbers back this up too. Good quality acrylic signs do more than just look nice. They actually help people find their way around better and make brands stand out more in commercial settings. This means businesses get both looks and functionality when they invest in proper acrylic installations.

Durable Displays for Automotive and Transportation

Acrylic boards have become really important in both automotive and transport sectors because they make those clear, tough displays everyone needs nowadays. Car manufacturers rely on them for dashboards and headlight covers since nobody wants cloudy plastic getting worse after a few months. The stuff stays crystal clear even when hit by road debris. Trains and buses also make good use of acrylic panels throughout their vehicles too. We see this material everywhere from ticket machines to emergency exit signs where people need to read information quickly. What makes acrylic so popular? Well, it lasts ages without cracking or yellowing, which means fewer replacements down the line. For fleet operators dealing with constant wear and tear, this translates into real savings over time while keeping passengers safe and informed at all times.

How to Select Reliable Acrylic Board Manufacturers

Certifications and Industry Compliance Standards

Looking for an acrylic board manufacturer? Check their certifications first. ISO and ASTM certifications really matter because they show a company cares about quality control. ISO certified manufacturers generally stick to strict rules when making sure their products are safe and good quality. ASTM standards tend to get into the nitty gritty details about materials used and how things should be done. Environmental compliance is another big one worth checking out. Companies serious about going green want to know their acrylic boards weren't made in ways that harm the planet. Some businesses even have specific requirements about recycling processes or energy usage during production. Taking time to verify all these papers and documents might seem tedious but it pays off in the long run. Most smart buyers find that manufacturers with proper certifications just feel more trustworthy overall.

Evaluating Production Capacity and Customization Expertise

Knowing what kind of production capacity a manufacturer has along with their customization skills makes all the difference when trying to get supply needs covered properly. Make sure they actually have what it takes to deal with big order volumes while still hitting those project timelines without letting quality slip. Some manufacturers go beyond basic stuff and offer really customized solutions, which puts them head and shoulders above companies stuck offering just standard off-the-shelf items. Looking at what they've done before gives good insight about whether they know their stuff and can be trusted. Check out case studies or talk to previous clients who can vouch for how well they handled special requests. When businesses take time to look at these factors, they find partners who don't just fill orders on time but also handle those tricky custom requirements that separate good suppliers from great ones.

FAQs

What are the benefits of using acrylic boards over glass?

Acrylic boards offer superior durability, are less prone to shattering, are lighter in weight, and have greater impact resistance compared to glass.

Can acrylic boards be used outdoors?

Yes, high-quality acrylic boards are UV-resistant, making them suitable for outdoor applications and resistant to fading under sunlight.

What are the differences between cell cast and extruded acrylic?

Cell cast acrylic is made with superior clarity and durability, while extruded acrylic is more cost-effective but may have subtle imperfections.

How can I ensure I choose a reliable acrylic board manufacturer?

Look for certifications such as ISO and ASTM, check compliance with environmental standards, and evaluate their production capacity and past project expertise.