fournisseurs de tôles en PVC mousseux

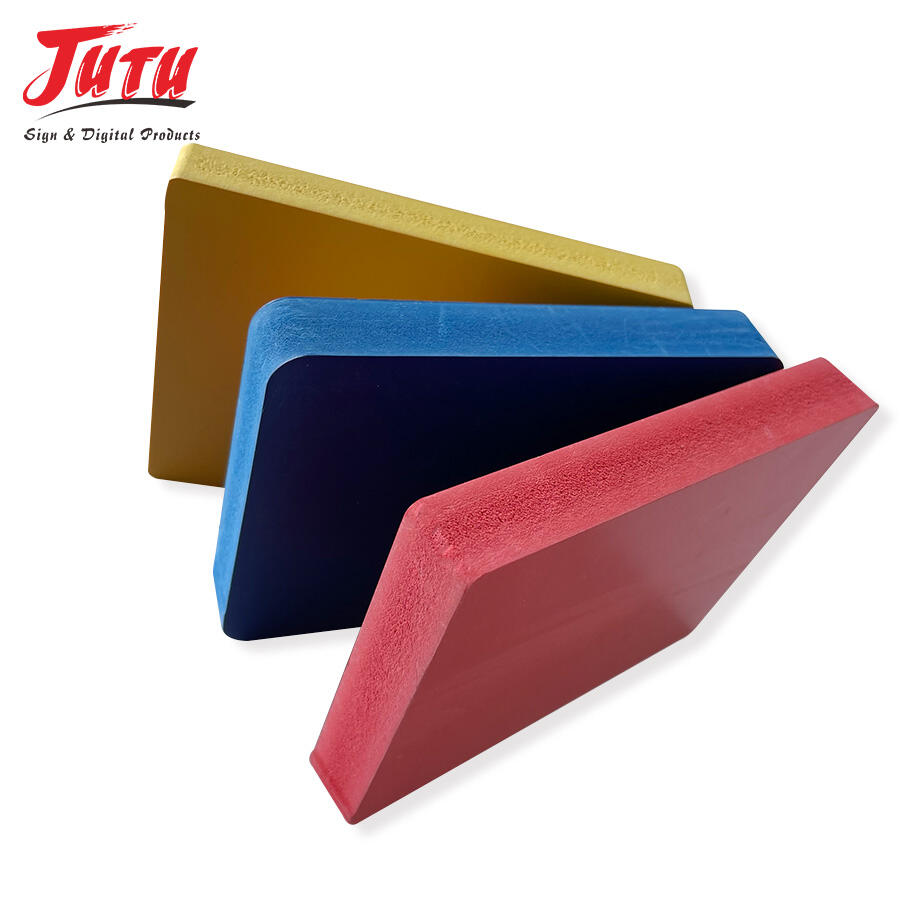

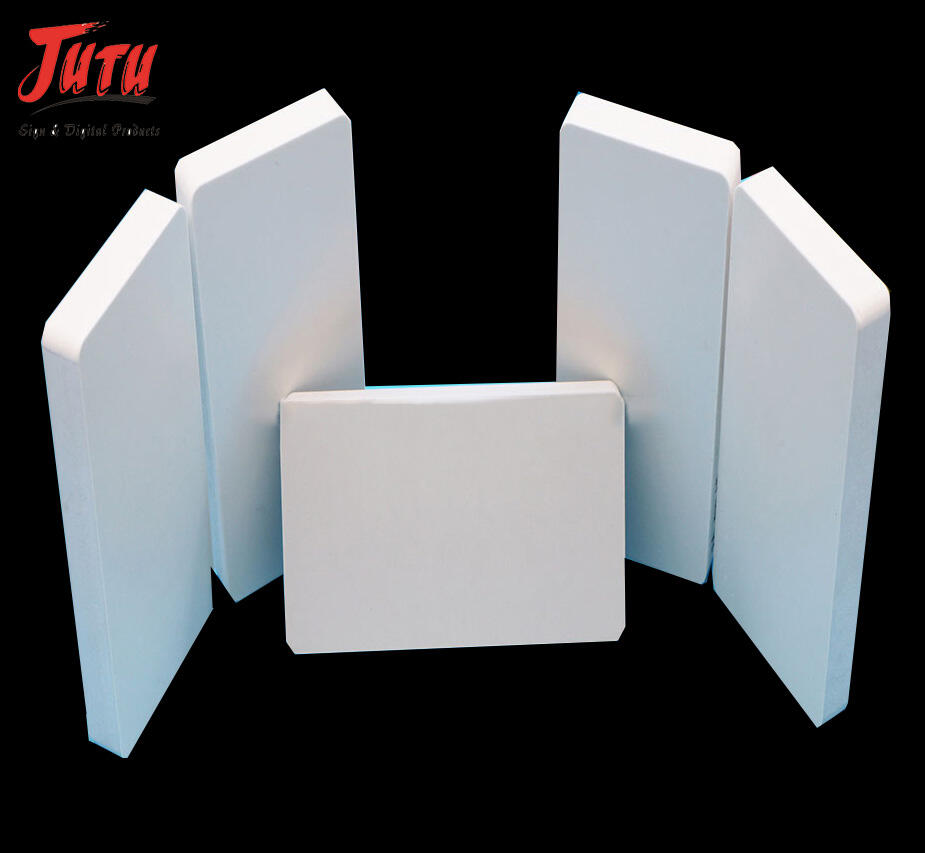

Les fournisseurs de feuilles en PVC expansé jouent un rôle crucial dans les industries modernes de la construction et de la fabrication, en proposant des matériaux plastiques polyvalents qui allient légèreté et durabilité exceptionnelle. Ces fournisseurs spécialisés offrent des feuilles de chlorure de polyvinyle expansé dotées d'une structure cellulaire unique créée par des procédés de moussage avancés. La fonction principale des feuilles en PVC expansé consiste à fournir des solutions économiques pour des applications nécessitant une résistance aux intempéries, une stabilité chimique et une précision dimensionnelle. Les principaux fournisseurs de feuilles en PVC expansé utilisent des technologies d'extrusion de pointe pour produire des matériaux présentant une structure cellulaire homogène et une répartition uniforme de la densité sur l'ensemble de chaque feuille. Les caractéristiques techniques de ces produits incluent d'excellentes propriétés d'isolation, une résistance supérieure aux chocs et une grande facilité de travail permettant un usinage, un perçage et une découpe aisés. Les fournisseurs modernes de feuilles en PVC expansé mettent en œuvre des systèmes de contrôle qualité garantissant des propriétés matérielles constantes d'un lot de production à l'autre, tout en respectant des tolérances strictes en matière d'épaisseur, de densité et de qualité de surface. Ces feuilles trouvent des applications étendues dans la fabrication d'enseignes, où leur finition de surface lisse et leur aptitude à être peintes en font des supports idéaux pour l'impression numérique et l'application de vinyle. Les professionnels de la construction s'appuient sur les fournisseurs de feuilles en PVC expansé pour des projets de bardage extérieur, de systèmes de cloisons intérieures et de maquettes architecturales. Le secteur maritime tire un bénéfice significatif de ces matériaux grâce à leur excellente résistance à l'humidité et à leur capacité à supporter des conditions environnementales difficiles. Dans le secteur des transports, on utilise ces feuilles pour les panneaux intérieurs des véhicules de loisirs, les composants aéronautiques et les garnitures automobiles. Les fabricants de meubles font de plus en plus appel aux fournisseurs de feuilles en PVC expansé afin de créer des composants légers mais robustes, résistants au fendillement, à la déformation et à la dégradation chimique. Ces feuilles conservent leur intégrité structurelle sur de larges plages de température, ce qui les rend adaptées aux installations intérieures comme extérieures. Les applications industrielles comprennent l'équipement de traitement chimique, les revêtements de cuves de stockage et les équipements spécialisés nécessitant des surfaces non réactives.