composite en aluminium plastique

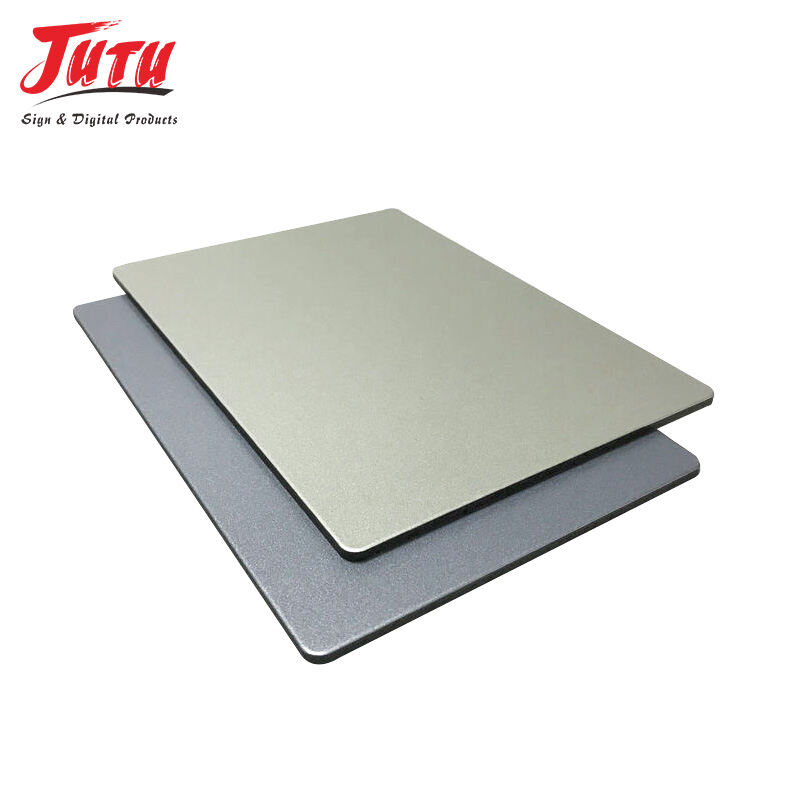

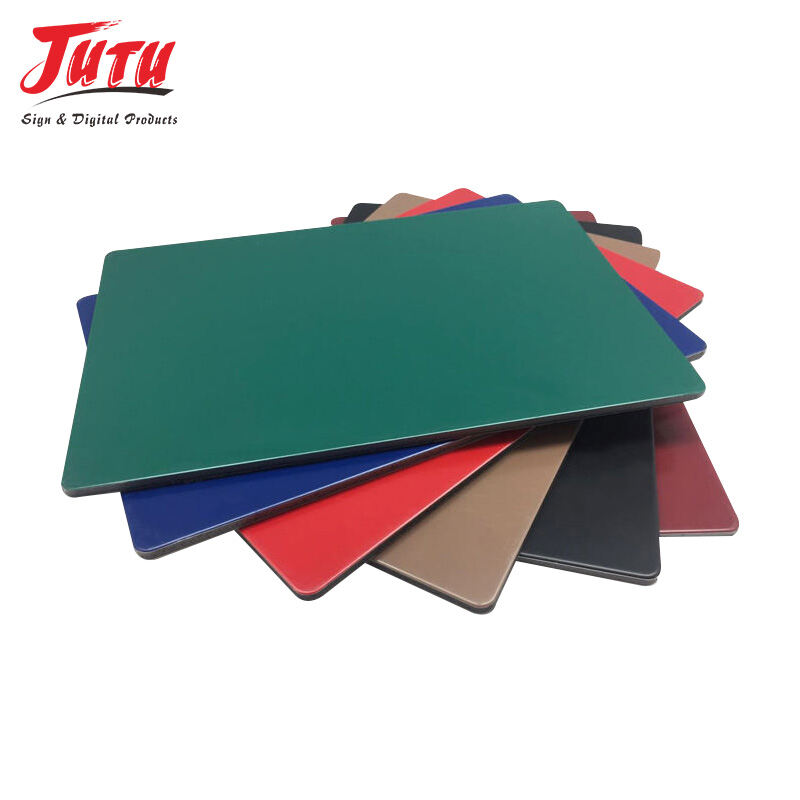

Le composite aluminium-plastique représente un matériau de construction révolutionnaire qui allie la résistance de l'aluminium à la polyvalence des polymères plastiques, créant un système de panneaux sophistiqué conçu pour les applications architecturales modernes. Ce matériau composite innovant est constitué de deux fines feuilles d'aluminium collées sur un noyau en polyéthylène, formant une structure légère mais incroyablement durable qui a transformé l'industrie de la construction. Le composite aluminium-plastique offre des performances exceptionnelles sur plusieurs plans, offrant aux architectes et constructeurs une solution fiable répondant à des exigences structurelles strictes tout en conservant un attrait esthétique. La base technologique du composite aluminium-plastique repose sur des techniques de collage avancées garantissant une adhérence permanente entre les couches métalliques et polymères, créant ainsi un matériau uni doté de propriétés mécaniques supérieures. Les procédés de fabrication impliquent un laminage continu sous des conditions contrôlées de température et de pression, produisant des panneaux présentant une qualité constante et une stabilité dimensionnelle. Les surfaces en aluminium offrent une excellente résistance aux intempéries et à la corrosion, tandis que le noyau plastique apporte flexibilité et résistance aux chocs. Cette combinaison unique permet au composite aluminium-plastique de résister à des conditions environnementales extrêmes, notamment les variations de température, l'exposition à l'humidité et au rayonnement UV. Les applications du composite aluminium-plastique s'étendent à de nombreux secteurs, allant des systèmes de bardage extérieur dans les bâtiments commerciaux aux éléments de design intérieur dans les projets résidentiels. Le matériau excelle dans les installations de murs-rideaux, où sa légèreté réduit les charges structurelles tout en offrant des performances thermiques remarquables. Les applications publicitaires profitent de la finition de surface lisse, qui accepte diverses techniques d'impression et de revêtement. Les secteurs des transports utilisent le composite aluminium-plastique pour les carrosseries de véhicules et les composants intérieurs, tirant parti de son rapport résistance-poids et de sa formabilité. La polyvalence du composite aluminium-plastique s'étend aux environnements marins, où sa résistance à la corrosion s'avère inestimable pour la construction navale et les structures offshore. Les capacités modernes de fabrication permettent des dimensions, couleurs et textures de surface personnalisées, permettant aux concepteurs d'atteindre des objectifs esthétiques spécifiques tout en respectant les exigences fonctionnelles.