Résistance exceptionnelle aux intempéries et longévité

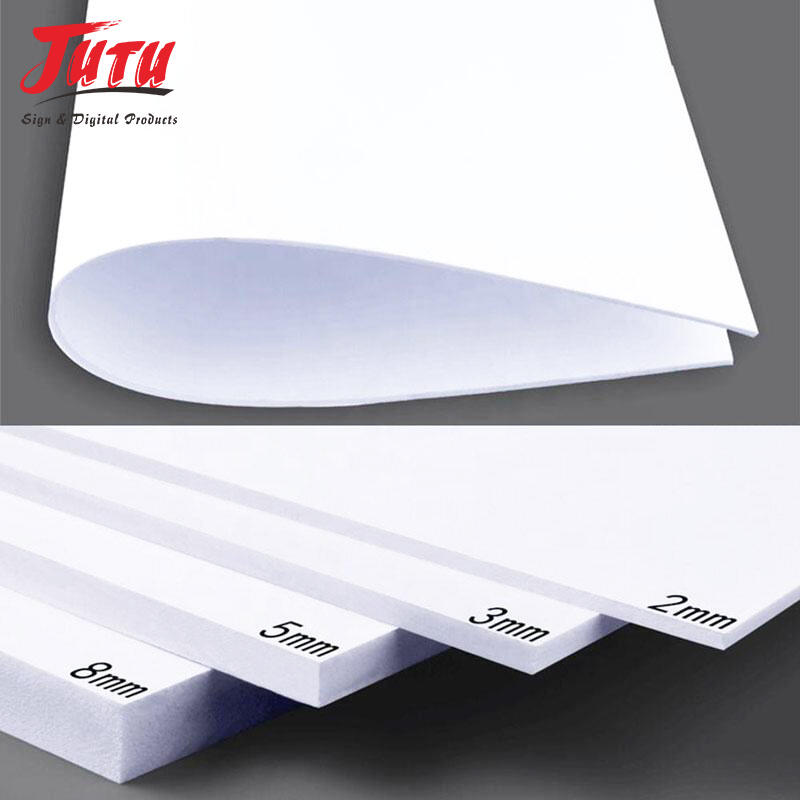

La plaque PVC de 2 mm se démarque sur le marché par ses capacités exceptionnelles de résistance aux intempéries, garantissant une performance durable dans des environnements extérieurs exigeants. Cette caractéristique remarquable provient d'une technologie avancée de stabilisation UV intégrée lors du processus de fabrication, qui empêche la dégradation habituellement subie par les matériaux plastiques exposés longtemps au soleil. Contrairement aux matériaux conventionnels qui s'écaillent, deviennent fragiles ou perdent leur intégrité structurelle sous l'exposition aux UV, la plaque PVC de 2 mm conserve sa couleur d'origine, sa flexibilité et sa résistance pendant plusieurs années de service fiable. Le matériau résiste sans problème aux variations extrêmes de température, sans se déformer, se fissurer ni subir de changements dimensionnels compromettant son fonctionnement. La pluie, la neige, l'humidité et l'exposition à l'air salin côtier ont un impact minimal sur les performances de la plaque, ce qui la rend idéale pour les applications marines, la signalétique extérieure et les éléments architecturaux. Cette résistance aux intempéries se traduit directement par des économies pour les utilisateurs, car le matériau élimine le besoin de remplacements fréquents, de revêtements protecteurs ou de procédures de maintenance intensives. La structure de surface non poreuse empêche l'absorption d'eau, évitant ainsi les dommages liés au gel-dégel observés dans d'autres matériaux, assurant une performance constante dans toutes les conditions climatiques. Les polluants chimiques, les pluies acides et les émissions industrielles ne peuvent pas pénétrer la surface, préservant à la fois l'apparence et les propriétés structurelles sur de longues périodes. Ce facteur de durabilité devient particulièrement précieux dans les applications commerciales où l'apparence influence l'image de marque et la perception du client. La plaque PVC de 2 mm conserve son aspect professionnel année après année, soutenant ainsi les objectifs commerciaux tout en minimisant les perturbations opérationnelles dues aux activités de maintenance et de remplacement. Les périodes de garantie dépassent souvent celles des matériaux alternatifs, reflétant la confiance des fabricants dans la performance à long terme et offrant une tranquillité d'esprit supplémentaire aux concepteurs de projets et aux utilisateurs finaux.