Außergewöhnliche Vielseitigkeit und Anpassungsmöglichkeiten für diverse Anwendungen

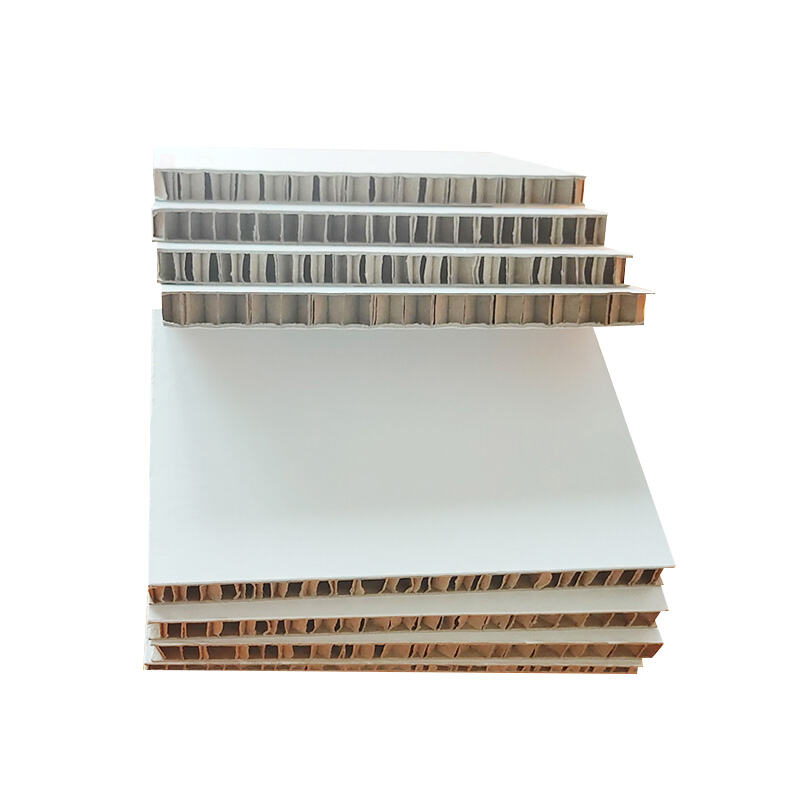

Die bemerkenswerte Vielseitigkeit der Harga-Wabenplatte ergibt sich aus ihrem anpassungsfähigen Konstruktionsrahmen, der unterschiedliche Anpassungsanforderungen in zahlreichen Branchen und Anwendungsszenarien erfüllt. Diese Flexibilität beginnt mit der Auswahl des Kernmaterials, wobei Hersteller Aluminium, Papier, Kunststoff oder spezialisierte Verbundwerkstoffe verwenden können, um bestimmte Leistungsanforderungen und Umweltbedingungen zu erfüllen. Jede Option für das Kernmaterial weist eigene Eigenschaften auf: Aluminiumkerne bieten hohe Festigkeit und Feuerbeständigkeit, Papierkerne zeichnen sich durch Kosteneffizienz und ökologische Nachhaltigkeit aus, während Kunststoffkerne eine verbesserte Beständigkeit gegen Feuchtigkeit und Chemikalien bieten. Die Auswahlmöglichkeiten für Deckschichten erweitern die Individualisierungsmöglichkeiten weiter, darunter Aluminium, Stahl, Glasfaser, Holzfurniere, Dekorlaminatplatten und Spezialbeschichtungen. Diese umfangreiche Materialpalette ermöglicht es der Harga-Wabenplatte, ästhetischen Ansprüchen gerecht zu werden, ohne dabei die funktionalen Leistungsstandards zu beeinträchtigen. Dickenvariationen reichen von dünnen Platten, die sich für leichte Anwendungen eignen, bis hin zu dicken Ausführungen für schwere Tragkonstruktionen, wodurch Ingenieure und Konstrukteure eine präzise dimensionale Kontrolle für optimale Projektergebnisse erhalten. Oberflächenbehandlungsoptionen umfassen glatte Oberflächen für Lackierung oder Laminierung, strukturierte Oberflächen zur Verbesserung des Grip oder der visuellen Wirkung sowie vorgefertigte Varianten, die zusätzliche Bearbeitungsschritte überflüssig machen. Die Farbanpassung erstreckt sich über Oberflächenbehandlungen hinaus und beinhaltet farbige Kernmaterialien sowie spezielle Deckschichten, die ein einheitliches Erscheinungsbild über die gesamte Plattendicke hinweg gewährleisten. Lochmuster können in die Deckschichten integriert werden, um akustische Anwendungen zu ermöglichen, wodurch schalldämpfende Platten für architektonische und industrielle Einsatzbereiche entstehen. Randbehandlungsoptionen umfassen versiegelte Kanten zum Schutz vor Feuchtigkeit, abgeschrägte Kanten für nahtlose Installationen sowie spezielle Profilierungen für mechanische Befestigungssysteme. Der Herstellungsprozess ermöglicht auch Sonderformen und -größen jenseits standardmäßiger rechteckiger Platten, einschließlich gekrümmter Abschnitte, komplexer Geometrien und integrierter Montageelemente. Spezialvarianten umfassen feuerbeständige Ausführungen gemäß strenger Sicherheitsvorschriften, maritime Versionen mit verbesserter Korrosionsbeständigkeit sowie lebensmittelechte Optionen für den Einsatz in professionellen Küchen. Diese umfassende Anpassungsfähigkeit positioniert die Harga-Wabenplatte als universelle Lösung, die sich an spezifische Projektanforderungen anpasst, anstatt Konstruktionskompromisse erzwingen zu müssen. Die Möglichkeit, Leistungsmerkmale gezielt anzupassen, während gleichzeitig Kosteneffizienz gewahrt bleibt, macht diese Platten besonders wertvoll für Spezialanwendungen, bei denen Standardmaterialien die einzigartige Kombination von Anforderungen nicht erfüllen können.