Außergewöhnliche Gestaltungsfreiheit und ästhetische Vielseitigkeit

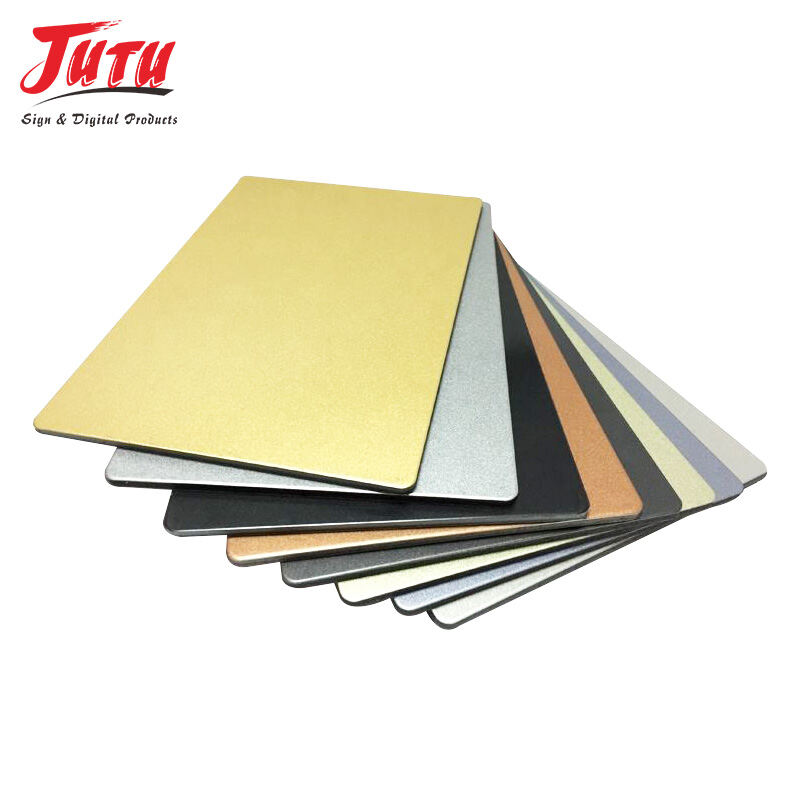

Die Alcopan-Aluminiumverbundplatte bietet eine beispiellose Gestaltungsfreiheit, die Architekten und Designern ermöglicht, innovative Fassaden und Innenelemente zu schaffen, die mit herkömmlichen Materialien nicht realisierbar wären. Die Fähigkeit des Materials, in komplexe Kurven, Winkel und dreidimensionale Formen geformt zu werden, eröffnet unbegrenzte kreative Möglichkeiten für Neubau- und Sanierungsprojekte. Fortschrittliche Fertigungstechniken ermöglichen es, Alcopan-Aluminiumverbundplatten mit Standard-Metallbearbeitungswerkzeugen zu schneiden, biegen, falzen und formen, wodurch maßgeschneiderte Designs auch für kleinere Projekte wirtschaftlich machbar werden. Die umfangreiche Farbpalette umfasst Volltonfarben, metallische Oberflächen, Holzoptiken, Steinformate und Sonderdrucke, die nahezu jede natürliche oder synthetische Oberfläche nachbilden können. Digitale Drucktechnologien ermöglichen die Anbringung von hochauflösenden Bildern, Unternehmenslogos und künstlerischen Motiven direkt auf die Oberfläche der Alcopan-Aluminiumverbundplatten und schaffen so einzigartige architektonische Akzente und markenspezifische Umgebungen. Die ebene, glatte Oberfläche des Materials bildet ein ideales Substrat für verschiedene Veredelungstechniken wie Pulverbeschichtung, Eloxierung und spezielle Behandlungen, die sowohl das Erscheinungsbild als auch die Leistungseigenschaften verbessern. Die Dimensionsstabilität gewährleistet, dass komplexe Geometrien ihre vorgesehene Form während Montage und Nutzungsdauer beibehalten und Verzerrungen verhindert werden, die das gewünschte ästhetische Erscheinungsbild beeinträchtigen könnten. Durch das geringe Gewicht der Alcopan-Aluminiumverbundplatten lassen sich großflächige architektonische Elemente ohne umfangreiche Tragkonstruktionen realisieren, was die Baukosten senkt und die Gestaltungsmöglichkeiten erweitert. Modulare Montagesysteme erlauben kreative Plattenanordnungen, darunter versetzte Muster, kontrastierende Farben und gemischte Texturen, die dynamische visuelle Effekte an Gebäudefassaden erzeugen. Die Kompatibilität des Materials mit verschiedenen Verglasungssystemen, tragenden Elementen und anderen Baumaterialien ermöglicht integrierte Konstruktionen, bei denen mehrere Materialien nahtlos kombiniert werden. Qualitätskontrollverfahren stellen eine Farbgleichmäßigkeit zwischen einzelnen Platten und Produktionschargen sicher und gewährleisten ein einheitliches Erscheinungsbild bei großflächigen Installationen. Die Möglichkeit, Sondergrößen anzugeben, reduziert Abfall und Montagezeit und erfüllt gleichzeitig besondere architektonische Anforderungen, die mit standardmäßigen Baustoffen nicht wirksam zu lösen sind.