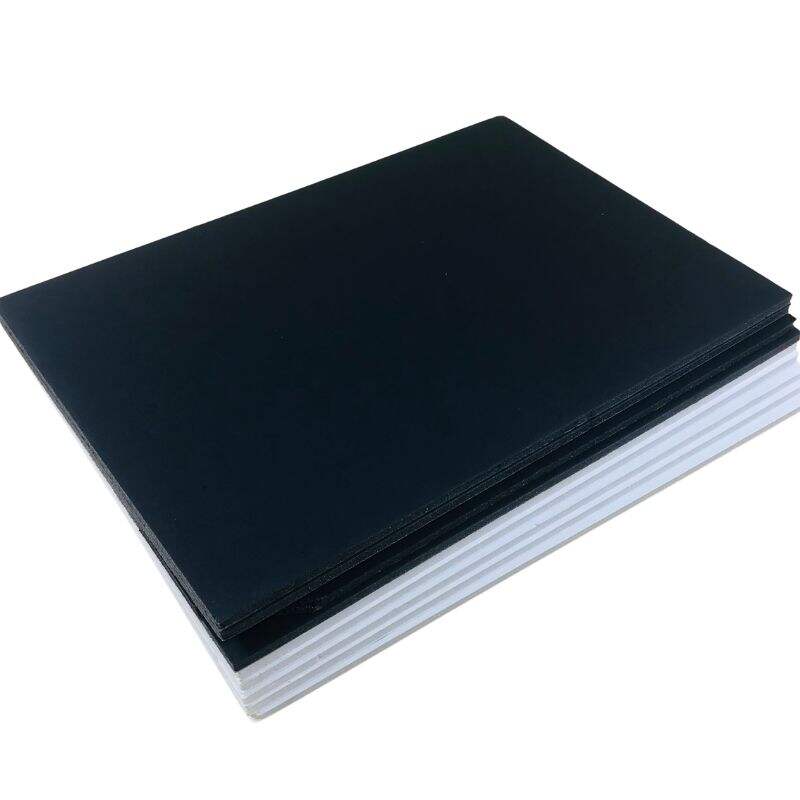

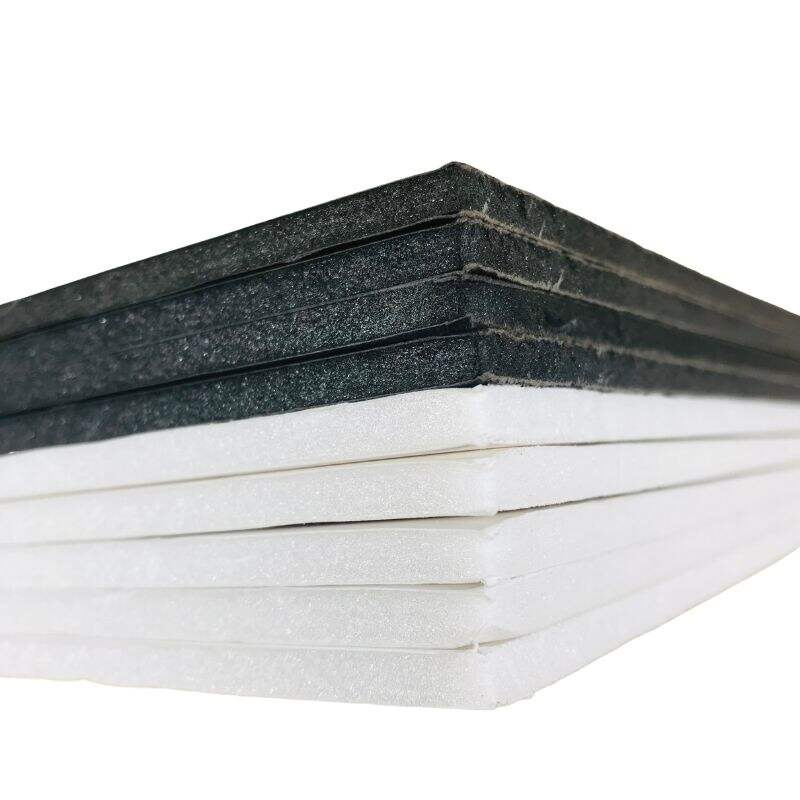

hersteller von Schaumblättern in der Größe a4

Ein Hersteller von A4-Schaumstoffplatten stellt eine spezialisierte Industrieunternehmen dar, das sich auf die Produktion leichter, vielseitiger Schaumstoffplatten speziell in Standardformat A4 (210 mm x 297 mm) konzentriert. Diese Hersteller nutzen fortschrittliche Produktionstechnologien, um hochwertige Schaumstoffplatten herzustellen, die für zahlreiche Branchen und Anwendungen geeignet sind. Die Hauptfunktion eines Herstellers von A4-Schaumstoffplatten besteht darin, Rohmaterialien – typischerweise Polystyrol- oder Polyurethan-Schaumkerne – in exakt dimensionierte Platten mit glatten, bedruckbaren Oberflächen umzuwandeln. Der Herstellungsprozess beinhaltet modernste Maschinen, die eine gleichbleibende Dicke, einheitliche Dichte und überlegene Oberflächenqualität jeder produzierten Platte sicherstellen. Zu den technologischen Merkmalen moderner Produktionsstätten für A4-Schaumstoffplatten gehören computergesteuerte Schneidesysteme, automatisierte Laminierverfahren und Qualitätskontrollmechanismen, die dimensionsgenaue Übereinstimmung innerhalb enger Toleranzen garantieren. Diese Hersteller setzen ausgeklügelte Schaumextrusionsverfahren, druckempfindliche Klebstoffapplikationen und Präzisionsschneidausrüstungen ein, um Produkte zu liefern, die internationalen Standards entsprechen. Der Produktionsablauf umfasst typischerweise die Vorbereitung des Schaumkerns, das Kaschieren der Oberfläche mit Papier oder Kunststofffolien, das Verkleben unter kontrollierten Druck- und Temperaturbedingungen sowie das endgültige Schneiden auf exakte A4-Maße. Die Anwendungsbereiche für Produkte eines Herstellers von A4-Schaumstoffplatten erstrecken sich auf zahlreiche Sektoren wie Werbung, Bildung, Architektur, Bastelanwendungen und professionelle Präsentationen. Diese Platten dienen als hervorragende Trägermaterialien für Digitaldruck, Fotomontagen, Erstellung von Displaymaterialien, architektonische Modellierung und Bildungsprojekte. Ihre leichte, aber steife Struktur macht sie ideal für temporäre Beschilderungen, Point-of-Sale-Displays, Kunstprojekte und Prototypenentwicklung. Bildungseinrichtungen nutzen diese Platten häufig für Schülerpräsentationen, Wissenschaftsmessen und Unterrichtsaktivitäten. Professionelle Designer und Architekten schätzen ihre einfache Bearbeitbarkeit beim Schneiden, Rillen und Formen für Konzeptmodelle und Designpräsentationen.