Understanding Paper Foam Board Dimensions for Optimal Performance

Paper foam board has become an increasingly versatile material across numerous industries, from architectural modeling to retail displays. The thickness of paper foam board plays a crucial role in determining its suitability for specific applications. Whether you're a professional designer, architect, or DIY enthusiast, selecting the right paper foam board thickness can make the difference between project success and disappointment.

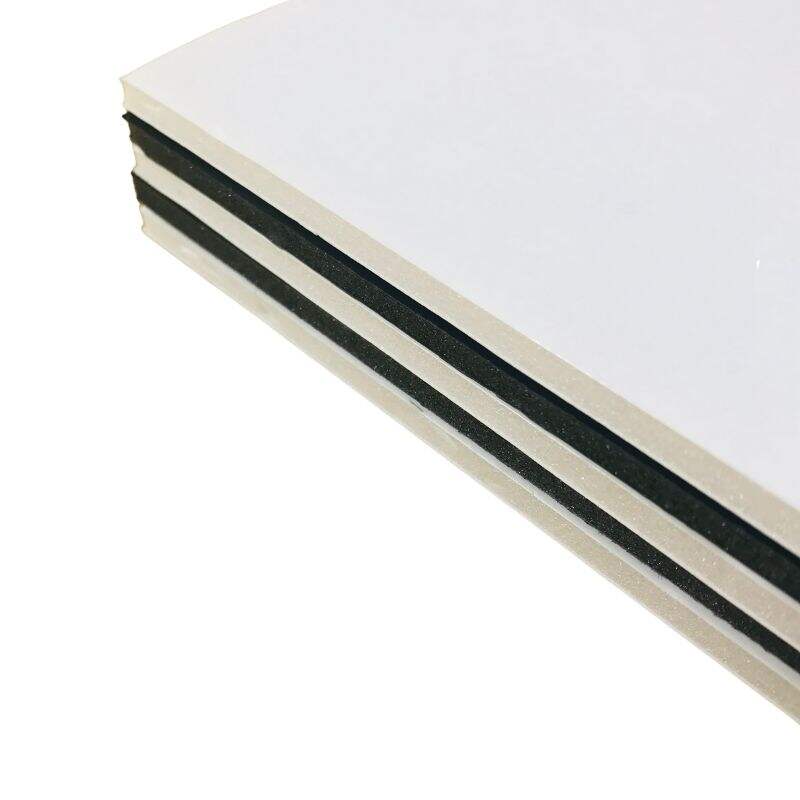

The market offers paper foam board in various thicknesses, typically ranging from 1/8 inch to 2 inches. Each thickness option serves distinct purposes and offers unique advantages. Understanding these differences helps ensure your projects achieve the desired structural integrity and visual impact while remaining cost-effective.

Common Paper Foam Board Thickness Options

Lightweight Thickness (1/8 inch - 1/4 inch)

The thinner variants of paper foam board are perfect for lightweight applications where flexibility and easy handling are priorities. These boards excel in temporary displays, presentation mounting, and quick mockups. The 1/8-inch thickness provides adequate rigidity for smaller projects while remaining easy to cut and manipulate.

When working with lightweight paper foam board thickness, professionals often appreciate its cost-effectiveness and storage efficiency. These boards can be stacked in larger quantities without taking up excessive space, making them ideal for high-volume projects or educational settings.

Medium Thickness (3/8 inch - 1/2 inch)

Medium-thickness paper foam board strikes an excellent balance between durability and manageability. This range is particularly popular in retail displays, exhibition booths, and architectural model making. The additional thickness provides enhanced stability while maintaining relatively easy handling characteristics.

These boards offer improved structural integrity compared to lighter options, making them suitable for free-standing displays and more demanding applications. The medium thickness range also provides better insulation properties, beneficial for certain display environments where temperature control is a consideration.

Heavy-Duty Thickness (3/4 inch - 2 inches)

For projects requiring maximum durability and structural strength, heavy-duty paper foam board thickness options deliver exceptional performance. These boards are commonly used in long-term installations, complex architectural models, and situations where robust support is essential.

The substantial thickness of these boards allows for creative construction techniques, including edge joining and layering, opening up new possibilities for complex designs and installations.

Selecting Thickness Based on Application Requirements

Interior Display Applications

For indoor displays and presentations, the choice of paper foam board thickness depends largely on the display size and duration. Temporary displays might function well with 1/4-inch boards, while permanent installations often benefit from 1/2-inch or thicker options to ensure longevity and stability.

Consider factors such as mounting methods, lighting requirements, and potential physical interaction when selecting thickness for interior applications. Heavier boards provide better resistance to warping and environmental changes, crucial for long-term installations.

Architectural Modeling Requirements

Architectural models demand precise thickness selection based on scale and detail requirements. Thinner boards (1/8 to 1/4 inch) work well for smaller scale models and detailed elements, while thicker options support larger-scale representations and structural components.

Professional model makers often combine different paper foam board thicknesses within the same project, utilizing each dimension's unique properties to achieve optimal results. This approach allows for both delicate detail work and robust structural elements in the same model.

Environmental Considerations and Durability

Temperature and Humidity Impact

Different paper foam board thicknesses respond differently to environmental conditions. Thicker boards generally offer better stability in varying temperature and humidity conditions, making them preferred for applications in less-controlled environments.

When selecting thickness for outdoor-adjacent installations or areas with significant environmental fluctuations, consider using boards 1/2 inch or thicker to minimize warping and maintain structural integrity over time.

Long-term Performance Factors

The longevity of paper foam board installations correlates directly with thickness selection. Thicker boards typically demonstrate better resistance to wear and tear, making them more cost-effective for permanent installations despite higher initial costs.

Consider the expected lifespan of your project when selecting board thickness. Short-term displays might perform adequately with thinner options, while long-term installations benefit from investing in thicker, more durable materials.

Cost-Benefit Analysis of Different Thicknesses

Material Investment Considerations

While thicker paper foam board options generally command higher prices, their enhanced durability and stability often justify the investment for appropriate applications. Consider the total project lifecycle when evaluating thickness options, including potential replacement costs for less durable solutions.

Budget-conscious projects might benefit from creative solutions, such as combining thinner boards or using structural supports to achieve desired stability without the cost of thicker materials.

Labor and Installation Efficiency

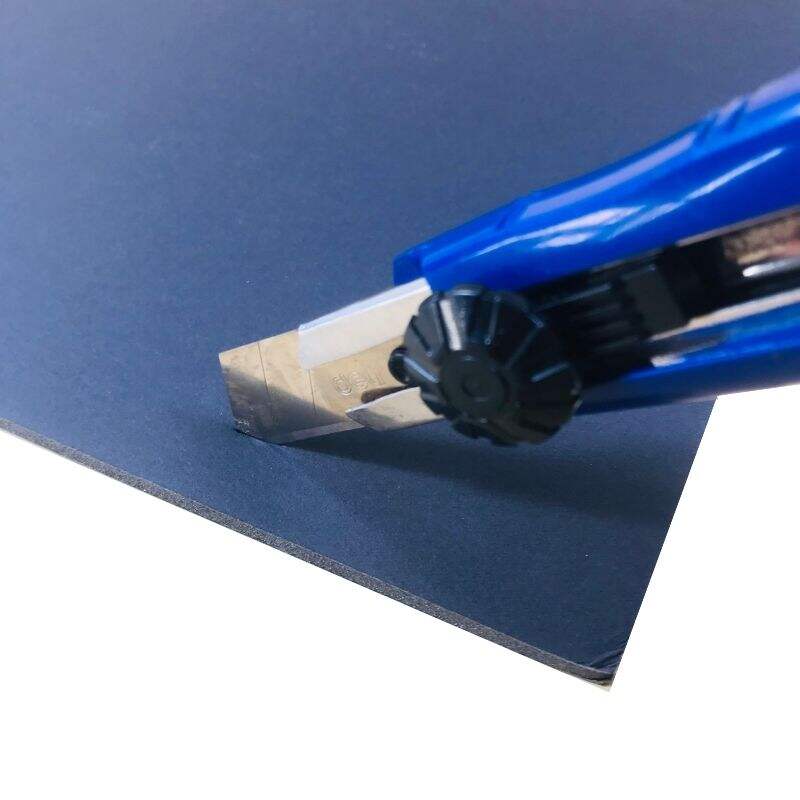

The chosen paper foam board thickness affects installation time and complexity. Thinner boards are typically easier to cut and manipulate but may require additional support structures. Thicker boards might need specialized cutting tools but often provide standalone stability.

Consider the available tools and expertise when selecting board thickness. Some projects might benefit from using medium-thickness boards that balance workability with structural integrity, optimizing both material and labor costs.

Frequently Asked Questions

How does paper foam board thickness affect cutting techniques?

The thickness of paper foam board significantly influences the cutting tools and techniques required. Thinner boards (1/8 to 1/4 inch) can typically be cut with standard craft knives and straight edges, while thicker boards may require specialized cutting tools or multiple passes. Professional-grade cutting equipment is recommended for boards 3/4 inch and thicker to ensure clean, precise cuts.

What thickness is best for outdoor display applications?

For outdoor displays, boards of at least 1/2 inch thickness are recommended to withstand environmental stresses. However, paper foam board is generally not advised for long-term outdoor use without proper protection from weather elements. Consider weather-resistant coatings or protective enclosures for outdoor applications.

Can different thicknesses be combined in a single project?

Yes, combining different paper foam board thicknesses in one project is common practice, especially in architectural modeling and complex displays. This approach allows designers to utilize the benefits of various thicknesses - using thinner boards for detail work and thicker boards for structural elements. Proper planning and joining techniques are essential for successful multi-thickness projects.