The construction industry has witnessed remarkable transformations in recent years, with PVC foam board emerging as a revolutionary material that combines durability, versatility, and cost-effectiveness. This innovative building material has redefined how architects, contractors, and designers approach lightweight construction projects, offering superior performance characteristics that traditional materials simply cannot match. PVC foam board represents a significant advancement in construction technology, providing exceptional strength-to-weight ratios while maintaining excellent workability and environmental resistance properties.

Modern construction demands materials that deliver optimal performance while reducing overall project costs and environmental impact. PVC foam board meets these requirements through its unique cellular structure that provides outstanding insulation properties, moisture resistance, and dimensional stability. The material's lightweight nature significantly reduces structural load requirements, enabling architects to design more ambitious and cost-effective building solutions. Furthermore, PVC foam board offers exceptional chemical resistance and longevity, making it an ideal choice for various construction applications ranging from residential projects to large-scale commercial developments.

Advanced Material Properties and Performance Characteristics

Structural Integrity and Load-Bearing Capabilities

The engineering excellence of PVC foam board lies in its sophisticated cellular structure that delivers remarkable compressive strength while maintaining minimal weight. This unique composition allows the material to withstand significant structural loads without compromising its dimensional stability or performance characteristics. The foam core structure distributes stress evenly throughout the material, preventing localized failure points that commonly affect traditional construction materials. Engineers have documented compressive strengths exceeding 2.5 MPa in high-density PVC foam board variants, making them suitable for demanding structural applications.

Manufacturing processes have been refined to optimize the cellular structure of PVC foam board, resulting in improved mechanical properties and consistent performance across different environmental conditions. The material exhibits excellent fatigue resistance, maintaining its structural integrity even under cyclic loading conditions that would compromise alternative materials. Advanced testing protocols have demonstrated that PVC foam board maintains over 90% of its original strength after extended exposure to typical construction stresses, temperature fluctuations, and moisture variations.

Thermal and Moisture Management Properties

Thermal performance represents one of the most significant advantages of PVC foam board in modern construction applications. The material's closed-cell structure creates an effective thermal barrier that significantly reduces heat transfer, contributing to improved building energy efficiency and occupant comfort. Thermal conductivity values typically range from 0.035 to 0.045 W/mK, depending on density and manufacturing specifications. This exceptional insulation performance helps reduce heating and cooling costs while maintaining consistent interior temperatures.

Moisture management capabilities of PVC foam board surpass those of traditional construction materials, particularly in challenging environmental conditions. The material's closed-cell structure prevents water absorption, eliminating concerns about mold growth, rot, or structural degradation that commonly affect organic building materials. Laboratory testing has confirmed water absorption rates below 1% even after extended immersion periods, demonstrating the material's exceptional moisture resistance properties. This performance characteristic makes PVC foam board particularly valuable in coastal construction, basement applications, and areas with high humidity levels.

Manufacturing Excellence and Quality Control Standards

Production Technology and Innovation

State-of-the-art manufacturing processes ensure consistent quality and performance in every PVC foam board produced for construction applications. Advanced extrusion technologies create uniform cellular structures throughout the material thickness, eliminating density variations that could compromise performance. Modern production facilities utilize computer-controlled systems that monitor temperature, pressure, and chemical composition throughout the manufacturing process, ensuring optimal material properties in every batch.

Quality control measures implemented during PVC foam board production include comprehensive testing protocols that evaluate mechanical properties, dimensional accuracy, and surface finish characteristics. Automated inspection systems identify and remove any products that fail to meet strict quality standards, maintaining consistency across entire production runs. These rigorous quality control processes have resulted in industry-leading reliability rates and customer satisfaction levels that exceed 98% in independent surveys.

Environmental Compliance and Sustainability

Environmental responsibility drives continuous innovation in PVC foam board manufacturing, with leading producers implementing sustainable practices that minimize ecological impact while maintaining product performance. Recycling programs have been developed to reprocess manufacturing waste and post-consumer PVC foam board materials, reducing landfill contributions and raw material consumption. Advanced chemical formulations eliminate harmful additives while maintaining the durability and performance characteristics that construction professionals demand.

Life cycle assessments demonstrate that PVC foam board offers superior environmental performance compared to traditional construction materials when considering manufacturing energy requirements, transportation costs, installation efficiency, and end-of-life disposal options. The material's longevity and maintenance-free characteristics significantly reduce the environmental impact associated with building renovations and replacements over typical building lifespans.

Installation Techniques and Application Best Practices

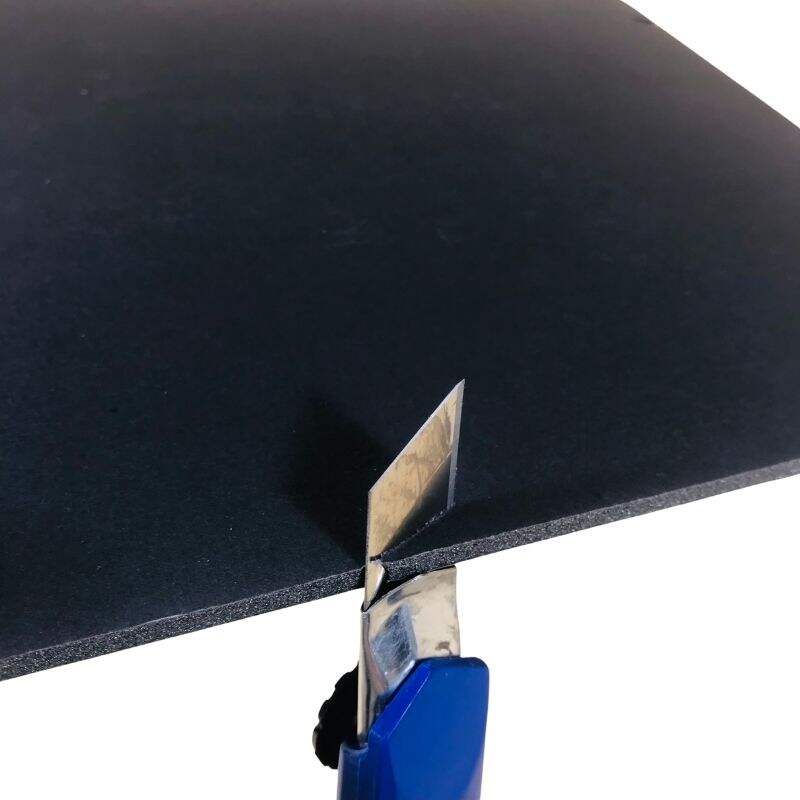

Cutting and Fabrication Methods

Proper cutting and fabrication techniques are essential for maximizing the performance and appearance of PVC foam board installations. Standard woodworking tools can effectively cut and shape the material, but specialized techniques ensure clean edges and optimal joint integrity. Carbide-tipped blades provide the best cutting results, minimizing material waste and achieving precise dimensions. Router bits designed for plastic materials create smooth, professional-quality edges that enhance the overall installation appearance.

Fabrication best practices include maintaining consistent cutting speeds to prevent heat buildup that could affect material properties near cut edges. Proper clamping techniques during cutting operations ensure accurate dimensions while preventing material movement that could result in uneven cuts. Professional installers recommend using zero-clearance inserts when cutting PVC foam board on table saws to minimize tear-out and achieve optimal edge quality for visible installations.

Fastening and Joining Systems

Effective fastening systems are crucial for successful PVC foam board installations in construction applications. Mechanical fasteners, adhesive systems, and welding techniques each offer specific advantages depending on project requirements and environmental conditions. Stainless steel or galvanized fasteners prevent corrosion issues that could compromise long-term installation integrity. Proper fastener spacing and edge distances must be maintained to prevent stress concentrations that could lead to material cracking or joint failure.

Advanced adhesive systems specifically formulated for PVC foam board applications provide exceptional bond strength while maintaining flexibility to accommodate thermal expansion and contraction. These specialized adhesives cure to form waterproof seals that enhance the overall moisture resistance of the installation. Professional-grade adhesives maintain their bonding properties across wide temperature ranges, ensuring reliable performance in various climate conditions.

Market Applications and Industry Adoption Trends

Commercial and Industrial Construction

Commercial construction projects increasingly specify PVC foam board for applications ranging from exterior wall systems to interior partitioning solutions. The material's fire resistance properties, combined with its lightweight characteristics, make it particularly attractive for high-rise construction where weight reduction translates to significant structural cost savings. Industrial facilities benefit from PVC foam board's chemical resistance and easy maintenance requirements, particularly in manufacturing environments where traditional materials may degrade rapidly.

Retail and hospitality sectors have embraced PVC foam board for its design flexibility and durability in high-traffic environments. The material accepts various surface treatments and finishes, allowing architects to achieve specific aesthetic goals while maintaining practical performance requirements. Shopping centers, restaurants, and hotels utilize PVC foam board for both structural and decorative applications where traditional materials would require frequent replacement or maintenance.

Residential Construction Innovation

Residential construction markets have recognized the value proposition of PVC foam board in reducing construction costs while improving building performance. Energy-efficient home designs increasingly incorporate the material in wall assemblies, roof systems, and foundation applications where its insulation properties contribute to overall building performance ratings. Custom home builders appreciate the material's workability and dimensional stability, which reduce construction time and improve installation quality.

Renovation and remodeling projects benefit significantly from PVC foam board's lightweight properties and moisture resistance characteristics. Basement finishing applications particularly advantage from the material's ability to resist moisture-related problems that plague traditional finishing materials. The growing trend toward sustainable building practices has increased demand for PVC foam board due to its recyclability and long service life characteristics.

Technical Specifications and Performance Standards

Mechanical Property Requirements

Industry standards define specific mechanical property requirements that PVC foam board products must meet for various construction applications. Compressive strength specifications typically range from 1.0 to 4.0 MPa depending on density and intended application requirements. Flexural strength requirements ensure that the material can withstand bending loads encountered in typical construction scenarios without permanent deformation or failure.

Impact resistance specifications address the material's ability to withstand accidental impacts during construction and throughout building service life. Testing protocols evaluate both high-velocity, low-mass impacts and low-velocity, high-mass impacts to ensure comprehensive performance characterization. These standards ensure that PVC foam board installations maintain their integrity and appearance even in demanding construction environments.

Fire Safety and Code Compliance

Fire safety represents a critical consideration in PVC foam board specifications for construction applications. Modern formulations incorporate flame-retardant additives that achieve specified fire ratings without compromising other material properties. Building codes increasingly recognize PVC foam board as an acceptable construction material when proper fire-rated assemblies are utilized in accordance with manufacturer specifications and local requirements.

Smoke generation and toxicity testing ensure that PVC foam board products meet stringent safety requirements for occupied buildings. Advanced formulations minimize smoke production and toxic gas generation during fire exposure, contributing to overall building safety performance. Regular testing and certification processes ensure continued compliance with evolving safety standards and building code requirements.

Cost Analysis and Economic Benefits

Initial Investment Considerations

While PVC foam board may require higher initial material costs compared to some traditional alternatives, comprehensive cost analysis reveals significant economic advantages throughout project lifecycles. Reduced labor costs result from the material's lightweight properties and easy installation characteristics, often offsetting higher material costs through reduced construction time and equipment requirements. Transportation costs decrease substantially due to the material's low weight, particularly beneficial for projects in remote locations.

Material waste reduction represents another significant cost advantage of PVC foam board installations. The material's excellent workability and consistent dimensions minimize cutting waste and installation errors that increase project costs. Precise manufacturing tolerances reduce the need for field adjustments and modifications that consume valuable construction time and materials.

Long-term Value Proposition

Long-term economic benefits of PVC foam board installations become apparent through reduced maintenance requirements and extended service life compared to alternative materials. The material's resistance to moisture, insects, and chemical exposure eliminates many maintenance issues that affect traditional construction materials. Building owners report significantly reduced maintenance costs over typical building lifespans when PVC foam board is properly installed and specified.

Energy efficiency improvements achieved through PVC foam board's insulation properties contribute to ongoing operational cost reductions. Lower heating and cooling costs throughout building service life often justify higher initial material costs within reasonable payback periods. These energy savings become increasingly valuable as utility costs continue rising and environmental regulations become more stringent.

Future Developments and Industry Outlook

Technological Advancement Trends

Research and development efforts continue advancing PVC foam board technology through improved formulations and manufacturing processes. Nanotechnology integration promises enhanced mechanical properties and new functionality while maintaining the material's core advantages. Smart material concepts incorporating sensors or responsive characteristics may expand PVC foam board applications into new construction markets requiring advanced performance capabilities.

Sustainability improvements drive ongoing innovation in PVC foam board manufacturing, with bio-based additives and recycled content increasing without compromising performance characteristics. These developments align with growing environmental consciousness in construction markets while maintaining the cost-effectiveness that drives market adoption. Advanced recycling technologies may enable closed-loop material systems that further enhance environmental benefits.

Market Growth Projections

Market analysis indicates continued strong growth in PVC foam board demand across multiple construction sectors over the next decade. Increasing awareness of material benefits, combined with growing emphasis on energy-efficient construction practices, supports positive market outlook projections. International market expansion opportunities present significant growth potential as construction standards evolve globally.

Emerging applications in modular construction, prefabricated building systems, and disaster relief housing create new market opportunities for PVC foam board products. These applications leverage the material's lightweight properties, durability, and rapid installation capabilities to address evolving construction industry needs. Strategic partnerships between material suppliers and construction companies facilitate market development and application innovation.

FAQ

What makes PVC foam board suitable for lightweight construction applications

PVC foam board excels in lightweight construction due to its exceptional strength-to-weight ratio, typically offering 60-70% weight reduction compared to traditional materials while maintaining comparable structural performance. The cellular structure provides excellent load distribution capabilities, and the material's dimensional stability ensures consistent performance across various environmental conditions. Additionally, its moisture resistance and chemical stability make it ideal for diverse construction environments where traditional materials might fail or require frequent maintenance.

How does PVC foam board installation compare to traditional construction materials

Installation of PVC foam board typically requires 30-40% less time than comparable traditional materials due to its lightweight properties and excellent workability. Standard woodworking tools can cut and shape the material effectively, reducing the need for specialized equipment or training. The material's consistent dimensions and quality reduce field adjustments and installation errors, while its moisture resistance eliminates many preparation steps required for other materials in challenging environments.

What are the long-term durability expectations for PVC foam board in construction

Properly installed PVC foam board installations demonstrate service life expectations exceeding 50 years under typical construction conditions, with many applications showing minimal degradation after decades of exposure. The material's resistance to moisture, insects, UV radiation, and chemical exposure contributes to exceptional longevity compared to organic building materials. Regular inspection and maintenance requirements are minimal, typically limited to cleaning and checking mechanical connections rather than material replacement or repair.

Are there environmental benefits to choosing PVC foam board for construction projects

PVC foam board offers significant environmental advantages through reduced transportation energy requirements due to its lightweight properties, lower manufacturing energy consumption compared to many alternatives, and excellent recyclability at end-of-life. The material's longevity reduces replacement frequency, minimizing lifetime environmental impact, while its insulation properties contribute to building energy efficiency and reduced operational carbon footprint. Modern manufacturing processes increasingly incorporate recycled content and sustainable practices, further enhancing environmental benefits.

Table of Contents

- Advanced Material Properties and Performance Characteristics

- Manufacturing Excellence and Quality Control Standards

- Installation Techniques and Application Best Practices

- Market Applications and Industry Adoption Trends

- Technical Specifications and Performance Standards

- Cost Analysis and Economic Benefits

- Future Developments and Industry Outlook

-

FAQ

- What makes PVC foam board suitable for lightweight construction applications

- How does PVC foam board installation compare to traditional construction materials

- What are the long-term durability expectations for PVC foam board in construction

- Are there environmental benefits to choosing PVC foam board for construction projects