What to Consider When Buying Aluminium Composite Panel

Aluminium composite panel, a versatile building material made of two thin aluminium sheets bonded to a core material, is widely used in construction, signage, and interior design. Its popularity stems from its lightweight nature, durability, and aesthetic appeal, making it suitable for both indoor and outdoor applications. However, not all aluminium composite panels are created equal—factors like core material, thickness, fire resistance, and certification can significantly affect performance and safety. Whether you’re buying for a building facade, a retail display, or a home renovation, knowing what to consider ensures you choose a panel that meets your needs, budget, and safety standards. This guide outlines the key factors to evaluate when buying aluminium composite panel.

Understand the Core Material

The core material of an aluminium composite panel is critical to its performance, weight, and safety. Different core materials offer varying benefits, so choosing the right one depends on your application:

- Polyethylene (PE) Core: The most common and affordable option, PE core panels are lightweight and flexible, making them easy to install. They are suitable for indoor applications, signage, or low-rise building facades where fire resistance is not a primary concern. However, PE is flammable, so these panels are not recommended for high-rise buildings or areas with strict fire codes.

- Mineral Core (MC): Mineral core panels use a non-combustible core made from minerals and binders, offering excellent fire resistance. They meet strict fire safety standards, making them ideal for high-rise buildings, hospitals, and public spaces where fire safety is critical. Mineral core panels are more expensive than PE core but provide greater peace of mind in fire-prone environments.

- Aluminium Honeycomb Core: These panels have a honeycomb structure core made from aluminium, combining strength and lightness. They offer high impact resistance and rigidity, suitable for structural applications like cladding, partitions, or furniture. They are also fire-resistant and durable but come at a higher cost.

Choosing the right core material ensures the aluminium composite panel performs well in its intended environment, balancing cost, safety, and functionality.

Check Thickness and Dimensions

The thickness of the aluminium sheets and the overall panel dimensions affect strength, durability, and installation:

- Aluminium Sheet Thickness: Most aluminium composite panels have aluminium sheets ranging from 0.1mm to 0.5mm thick. Thicker sheets (0.3mm or more) offer better impact resistance and rigidity, making them suitable for outdoor facades or high-traffic areas. Thinner sheets are lighter and cheaper, ideal for indoor displays or low-stress applications.

- Overall Panel Thickness: Panels typically range from 3mm to 10mm in total thickness. Thicker panels (5mm or more) are stronger and more stable, reducing the risk of warping in outdoor conditions. Thinner panels are more flexible, easier to bend or shape, and better for curved designs.

- Panel Size: Aluminium composite panels come in standard sizes (e.g., 1220mm x 2440mm or 1500mm x 3000mm), but custom sizes are available. Consider your project’s dimensions to minimize waste—larger panels reduce the number of joints, improving aesthetics and reducing installation time.

Matching thickness and size to your project’s needs ensures the panel is strong enough for the application without being unnecessarily heavy or costly.

Evaluate Fire Resistance and Safety Standards

Fire safety is a critical consideration, especially for outdoor building facades or public spaces. Aluminium composite panels vary widely in their fire performance:

- Flammability Ratings: Look for panels tested to international standards like EN 13501-1 (European) or ASTM E84 (US). PE core panels often have a flammability rating of B-s3,d2 (combustible with moderate smoke), while mineral core panels achieve A2-s1,d0 (non-combustible with low smoke), meeting strict fire codes.

- Local Building Regulations: Many countries have specific regulations for aluminium composite panels in high-rise buildings. For example, after past fire incidents, some regions ban PE core panels in buildings over a certain height, requiring mineral core or non-combustible alternatives. Always check local codes to ensure compliance.

- Fire Spread Risk: PE core panels can melt and spread fire quickly, while mineral core panels resist burning and limit fire spread. Investing in fire-resistant panels reduces the risk of property damage and ensures safety in case of a fire.

Never compromise on fire resistance—choosing a panel that meets safety standards is essential for protecting lives and property.

Assess Durability and Weather Resistance

Aluminium composite panels must withstand environmental conditions, especially for outdoor use:

- Corrosion Resistance: Aluminium naturally forms a protective oxide layer, but panels exposed to harsh environments (coastal areas with salt spray, industrial zones with chemicals) need extra protection. Look for panels with a fluoropolymer (PVDF) coating, which resists corrosion, UV damage, and fading. Panels with a polyester coating are cheaper but less durable in extreme weather.

- UV Resistance: Outdoor panels should resist fading and discoloration from sunlight. PVDF coatings are UV-stable, ensuring the panel retains its color for 15–20 years. Polyester coatings may fade in 5–10 years, requiring repainting or replacement.

- Impact Resistance: The panel should withstand minor impacts from hail, debris, or installation tools without denting or cracking. Thicker aluminium sheets and rigid cores (like mineral or honeycomb) improve impact resistance.

- Temperature Tolerance: Panels should remain stable in extreme temperatures, avoiding warping in heat or cracking in cold. Quality panels resist thermal expansion and contraction, maintaining their shape over time.

Durable panels reduce maintenance costs and ensure your project looks good for years, even in harsh conditions.

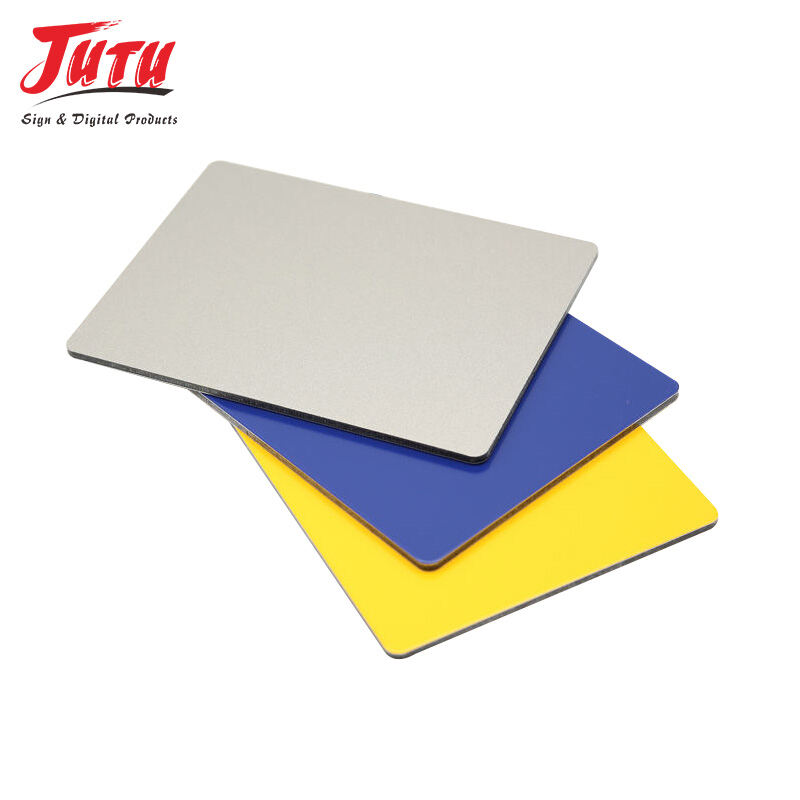

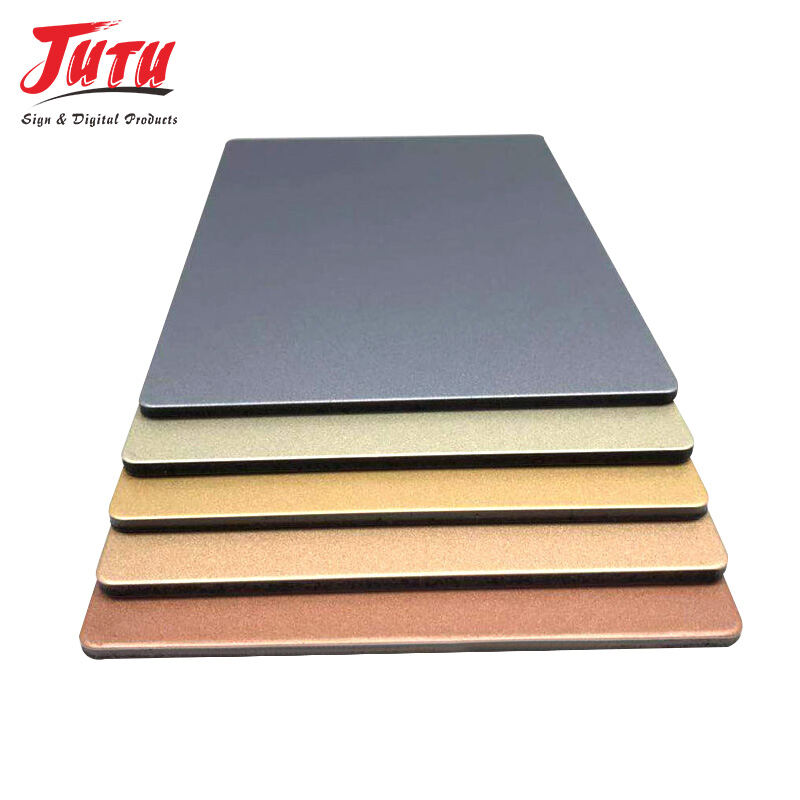

Consider Aesthetics and Finish Options

Aluminium composite panels offer a range of aesthetic options to match your design vision:

- Color and Finish: Panels come in solid colors, metallic finishes, wood or stone textures, and even custom prints. PVDF coatings offer a wider range of colors and better color retention than polyester coatings. Choose a finish that complements the project’s design—matte for a modern look, metallic for a sleek finish, or textured for added visual interest.

- Surface Quality: The surface should be smooth, with no bubbles, scratches, or uneven coloring. Consistent quality ensures a professional appearance, especially for large facades or visible applications.

- Customization: Some manufacturers offer custom cutting, bending, or perforation for unique designs. This is useful for signage, decorative screens, or architectural features that require specific shapes or patterns.

Aesthetics are important, but balance them with durability—choose a finish that looks good and stands up to the environment.

Check Certification and Quality Assurance

To ensure you’re buying a reliable product, look for certifications and quality guarantees:

- Manufacturer Certifications: Reputable manufacturers provide certificates for fire resistance, durability, and coating quality (e.g., AAMA 2605 for high-performance coatings). These certifications verify that the panel meets industry standards.

- Warranty: A good warranty indicates confidence in the product. Look for warranties covering fading, corrosion, or delamination (separation of aluminium sheets from the core) for 10–20 years. Avoid panels with no warranty or short-term guarantees.

- Quality Control: Ask about the manufacturer’s quality control processes. Panels should undergo testing for strength, adhesion, and weather resistance before leaving the factory. Visiting the manufacturer or checking reviews can help assess quality.

Certifications and warranties provide peace of mind that the aluminium composite panel will perform as expected.

Compare Costs and Value

While price is a factor, focus on value rather than the lowest cost:

- Initial Cost: PE core panels are the cheapest, followed by mineral core, then honeycomb core. However, cheaper panels may cost more in the long run due to maintenance, repairs, or early replacement.

- Installation Costs: Lightweight panels are easier to install, reducing labor costs. Panels with pre-applied adhesives or easy-to-cut designs can also lower installation time and expenses.

- Long-Term Costs: Fire-resistant, durable panels with long warranties reduce replacement and maintenance costs. For example, a PVDF-coated panel may cost more upfront but won’t need repainting, saving money over 10–20 years.

Consider the total lifecycle cost, not just the initial price, to choose the best value for your project.

FAQ

What is the lifespan of an aluminium composite panel?

With proper installation and maintenance, high-quality aluminium composite panels can last 15–30 years. PE core panels may last 10–15 years, while mineral core or PVDF-coated panels can exceed 20 years.

Can aluminium composite panels be used outdoors?

Yes, but choose panels with PVDF coatings and fire-resistant cores for outdoor use. They resist UV damage, corrosion, and weathering better than indoor-focused panels.

Are aluminium composite panels recyclable?

Yes, most aluminium composite panels are recyclable. The aluminium sheets can be melted down and reused, and some core materials (like mineral or aluminium honeycomb) are also recyclable.

How do I know if an aluminium composite panel is fire-resistant?

Check for certifications like EN 13501-1 A2-s1,d0 or ASTM E84 Class A. Manufacturers should provide test reports proving fire resistance.

What’s the difference between PVDF and polyester coatings?

PVDF coatings are more durable, UV-resistant, and color-stable, lasting 15–20 years. Polyester coatings are cheaper but fade faster, lasting 5–10 years, making them better for indoor use.