PVC foam board is a versatile material used in everything from signs and crafts to furniture and construction. It’s lightweight, durable, and easy to work with, but not all PVC foam boards are the same. Choosing the right one depends on your project’s needs—like how much weight it will hold, whether it’s used indoors or outdoors, and how it will be shaped or decorated. Let’s break down the key factors to consider when picking a PVC foam board for your project.

Consider the Thickness

PVC foam board comes in various thicknesses, from 1mm (thin) to 50mm (thick). The right thickness depends on what you’re building.

- Thin boards (1–5mm): These are lightweight and flexible, making them great for projects like signs, posters, or craft decorations. A 3mm PVC foam board, for example, works well for a store sign that needs to be mounted on a wall—it’s easy to cut into shapes and won’t weigh down the mounting hardware.

- Medium boards (6–15mm): Sturdier than thin ones, they’re good for projects that need a bit of structure. Use 10mm PVC foam board for shelving in a craft room, display cases, or lightweight furniture parts (like drawer dividers). They hold their shape but are still easy to cut with basic tools.

- Thick boards (16–50mm): These are rigid and strong, ideal for structural uses. A 25mm PVC foam board can support weight, so it’s perfect for outdoor benches, garden planters, or as a base for heavy equipment. Thick boards are also good for projects that need insulation, like DIY coolers or soundproofing panels.

Choosing the wrong thickness can cause problems: a board too thin might bend under weight, while one too thick could be hard to cut or add unnecessary bulk.

Check the Density

PVC foam board’s density (how much it weighs per unit volume) affects its strength and flexibility. Density is usually measured in kg/m³, with options ranging from 200kg/m³ (low) to 800kg/m³ (high).

- Low-density (200–400kg/m³): Lightweight and easy to cut, but less strong. They’re best for decorative projects—like 3D wall art, party decorations, or model making. A low-density PVC foam board is easy to carve or shape with a knife, making it great for crafts.

- Medium-density (400–600kg/m³): A balance of strength and weight. They work for most general projects: indoor signs, cabinet panels, or shelf liners. A medium-density PVC foam board can handle light impacts and is durable enough for daily use.

- High-density (600–800kg/m³): Strong and rigid, suitable for heavy-duty use. Use them for outdoor furniture, structural supports (like in DIY sheds), or projects that need to resist wear (like floor tiles). High-density PVC foam board is harder to cut but won’t crack or warp under pressure.

For example, a high-density board is a must if you’re building a outdoor table that will hold heavy dishes, while a low-density board is fine for a kids’ craft project.

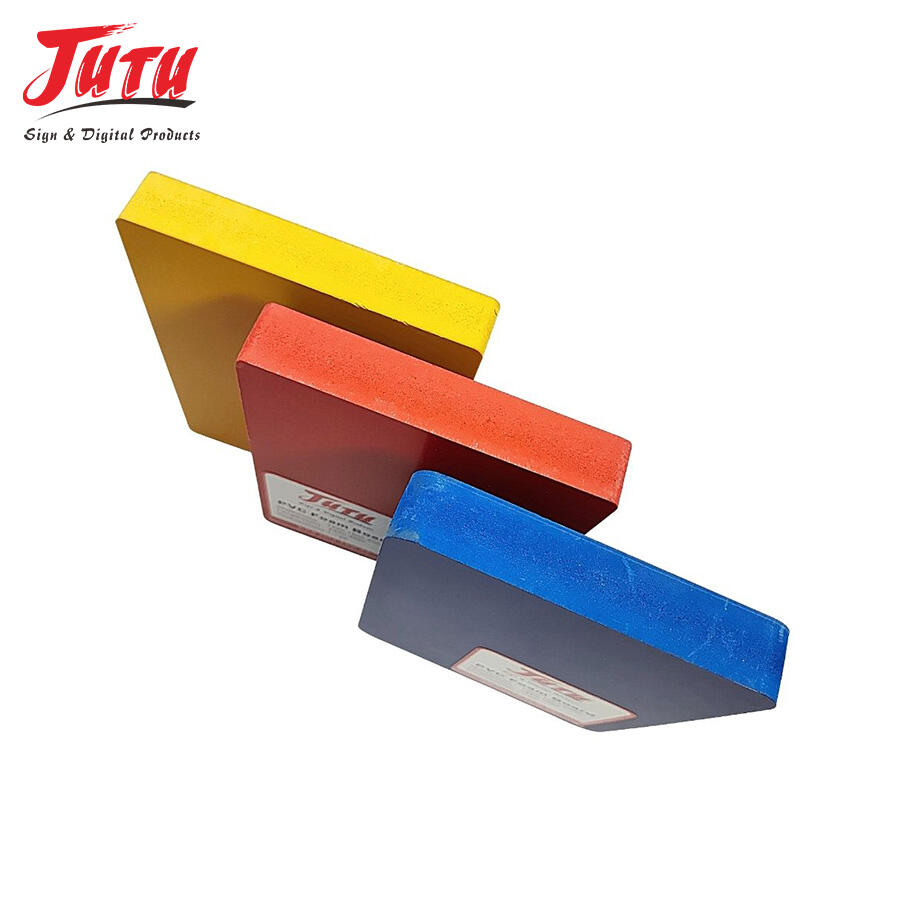

Look at Surface Finish

PVC foam board comes with different surface finishes, each suited to specific projects—especially those involving printing, painting, or texture.

- Smooth surface: Most common and best for printing, painting, or applying stickers. A smooth PVC foam board takes ink or paint evenly, making it ideal for signs, banners, or wall decals. The smooth surface also makes cleaning easy—spills wipe off without leaving marks.

- Textured surface: Some boards have a rough or patterned surface (like wood grain or concrete). These are great for decorative projects where you want a specific look, such as fake stone walls for a theater set or wood-like shelves. Textured PVC foam board hides small scratches better than smooth ones, so it’s good for high-traffic areas.

- Matte vs. glossy: Matte surfaces reduce glare, making them good for outdoor signs or displays in bright light. Glossy surfaces are shiny and eye-catching, perfect for indoor posters or retail displays.

Match the surface finish to your project’s needs: printing or painting? Go smooth. Decorative or high-traffic? Try textured.

Evaluate Weather Resistance

If your project is outdoors (or in a damp area like a bathroom), you need a PVC foam board that can handle moisture, sunlight, and temperature changes.

- Outdoor-rated PVC foam board: These are treated to resist UV rays (so they won’t fade), water (so they won’t swell), and mold. Look for labels like “UV-stabilized” or “weather-resistant.” Use them for outdoor signs, garden decor, or poolside furniture.

- Indoor-only boards: Cheaper and not treated for the elements, they work well inside dry areas (living rooms, offices). They may warp or discolor if exposed to rain or humidity, so avoid using them outdoors.

For example, a weather-resistant PVC foam board is a must for a backyard sign that will sit in rain and sun, while an indoor board is fine for a bookshelf in a dry bedroom.

Check Size and Cutability

PVC foam board comes in standard sizes (like 4x8 feet), but you may need to cut it to fit your project. Consider how easy it is to work with.

- Standard sizes: Most stores carry 4x8 feet or 3x6 feet boards. If your project fits these sizes (like a large sign), buying a full sheet saves time.

- Custom cutting: If you need smaller pieces, check if the board cuts cleanly. PVC foam board is easy to cut with a utility knife, saw, or laser cutter, but high-density boards may need sharper tools. Avoid boards that crack or splinter when cut—this can ruin your project.

- Edge finish: After cutting, some boards have rough edges. Look for PVC foam board that sands smoothly if you need a polished look (like furniture edges).

For DIY projects, choose a board that’s easy to cut with the tools you have—no need for expensive equipment unless you’re working with thick, high-density boards.

Compare Cost and Quality

Price varies based on thickness, density, and treatment. Don’t just pick the cheapest—balance cost with quality.

- Budget boards: Good for short-term or simple projects (party decorations, temporary signs). They may be less dense or not as smooth, but they get the job done.

- Mid-range boards: Offer better density and surface finish, suitable for most home or small business projects (shelves, indoor signs).

- Premium boards: Weather-resistant, high-density, or custom-finished, they’re worth the cost for long-term outdoor projects or high-quality displays (retail store fixtures, permanent outdoor signs).

Spend more for projects that need to last (outdoor, structural) and save on temporary or simple indoor uses.

FAQ

What’s the difference between PVC foam board and regular PVC board?

PVC foam board has a foam core, making it lighter and easier to cut. Regular PVC board is solid and heavier, better for very strong structural uses.

Can PVC foam board be painted?

Yes, but use paint made for plastic (acrylic or latex). Sand the surface lightly first to help the paint stick, then apply 2–3 coats.

How much weight can a PVC foam board hold?

It depends on density and thickness. A 10mm high-density board can hold 5–10kg per square foot (like books on a shelf), while a low-density board may only hold 1–2kg.

Is PVC foam board waterproof?

Most are water-resistant, but outdoor-rated ones are fully waterproof. Indoor boards resist spills but may warp if submerged.

Can I use PVC foam board for food-related projects (like a display case)?

Yes, but choose food-safe PVC foam board (look for FDA-approved labels). It’s easy to clean and won’t leach chemicals.