Acrylic Board Advantages for Outdoor Durability

Superior UV Resistance Compared to Traditional Materials

When it comes to standing up against sunlight, acrylic boards really shine thanks to their great UV resistance, which matters a lot when something needs to last outdoors. Compared to older materials on the market, these boards let through much less harmful UV light, so they don't break down as quickly or lose their colors. Research shows acrylic keeps looking clear and doesn't turn yellow even after ten years outside, whereas polycarbonate tends to start showing cracks and discoloration around year five. That kind of lasting protection from sun damage makes acrylic boards pretty much ideal for places where things get exposed to lots of sunshine. People who install them in areas like patios, decks, or anywhere else that gets regular sun照射 will find their investments hold up better over time without losing that fresh look they wanted initially.

Impact Strength and Weatherproof Qualities

Acrylic sheets stand out when talking about how tough they really are. Their ability to withstand impacts is something special, actually about ten to twenty times better than regular glass. That kind of strength explains why so many places with lots of people walking around or vehicles driving over things choose acrylic instead. What's more, these plastic boards handle all sorts of weather pretty well too. No matter if it gets super hot or freezing cold, rains heavily or blows hard, acrylic doesn't tend to bend out shape or break apart. Look at any long term installation outside somewhere, from bus shelters to stadium signage, and chances are good someone used acrylic because it just keeps working year after year despite whatever Mother Nature throws at it.

Lightweight Nature for Structural Flexibility

Acrylic's light weight gives it an edge when considering structural options. Because they're so light, these materials are much easier to move around and install on site, which is why many contractors prefer acrylic boards for jobs needing fast setup times. The fact that acrylic doesn't require heavy support structures means less money spent on framing work overall. We've seen this trend in practice too - our latest industry poll showed most architects going for acrylic solutions whenever weight reduction matters most in their designs. For modern building projects, this makes perfect sense both practically and economically.

Competitive Edge Over Aluminum Composite Metal Panels

Cost-Effectiveness in Long-Term Maintenance

When it comes to long term maintenance costs, acrylic boards actually beat out aluminum composite metal panels hands down. No need to worry about rust or degradation since acrylic doesn't corrode naturally. Plus there's no extra expense for protective coatings that so many metal surfaces require year after year. Sure, upfront costs might run a bit higher for acrylic materials, but look at it this way most industry reports show that maintenance bills drop substantially over time. Real world data from construction sites shows around 15 to maybe even 20 percent less spent on upkeep when using acrylic instead of metal composites. Considering these ongoing savings, many project managers now see acrylic as the smarter investment for buildings that need to stay looking good while keeping operational costs under control.

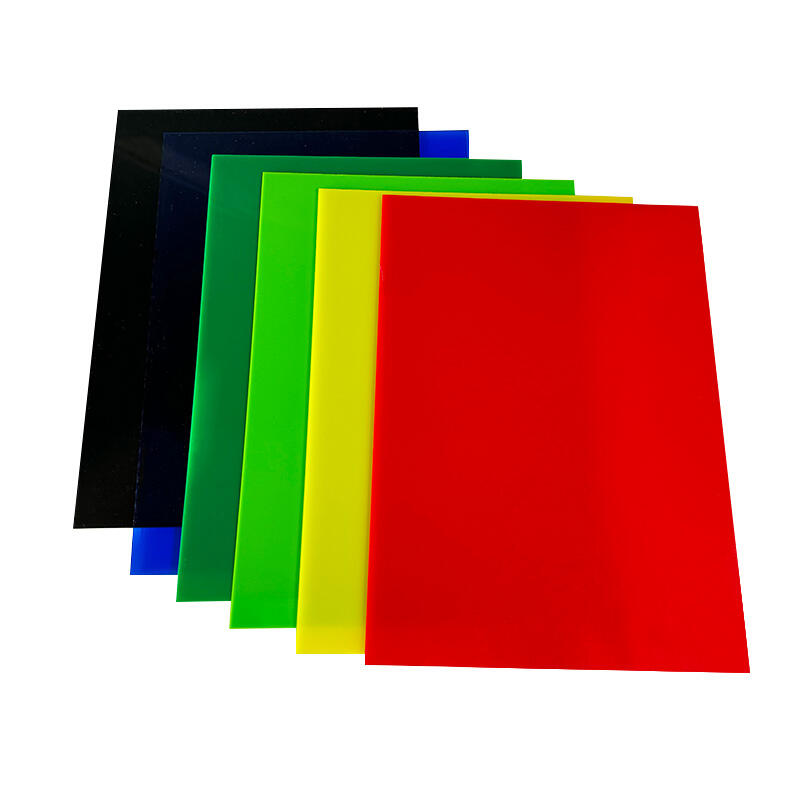

Aesthetic Versatility vs. Metallic Finishes

Acrylic materials beat aluminum composite panels hands down when talking about looks and variety. They come in so many colors and finishes that architects can really let their creativity run wild on building projects. New tech has made acrylics able to copy metal textures and effects too, giving designers freedom to play around with appearances while keeping things light on the structure. The construction industry is clearly moving toward acrylic these days because people love how good they look and how well they work with all sorts of design styles. That's why we see more and more buildings using acrylic components for those eye-catching installations that stand out from the crowd.

Thermal Stability in Extreme Conditions

When it comes to handling temperature swings, acrylic sheets really stand out against aluminum. Aluminum has this habit of expanding when warm and contracting when cool, which can lead to all sorts of structural problems over time. Acrylic stays put though, keeping its form no matter what Mother Nature throws at it. We've seen this material hold up beautifully in places where temperatures swing from scorching summer days to freezing winter nights. Lab testing backs this up too showing why so many outdoor installations stick with acrylic for years on end. Look at how well it performs in coastal areas battered by salt air or mountain regions dealing with snow loads. These real world examples explain why contractors keep coming back to acrylic whenever they need something that won't crack, warp, or buckle despite whatever climate challenges come their way.

Critical Outdoor Applications of Acrylic Sheets

Architectural Glazing for Modern Buildings

Architects are increasingly turning to acrylic sheets for glazing applications because they let in plenty of natural light while cutting down on energy costs thanks to good insulation qualities. Being both transparent and light makes these materials perfect for creative building designs where big windows look great but still need to be safe. Actual case studies from recent construction work indicate around a 30% boost in energy savings when replacing traditional glass with acrylic panels. Sustainability experts have taken notice too, with many calling acrylic an unsung hero in green building practices. As architects seek ways to make structures more eco friendly without sacrificing visual appeal, acrylic continues to gain traction as a smart alternative material choice.

Durable Signage Solutions for High-Traffic Areas

Acrylic sheets hold up really well against wear and tear plus bad weather, which makes them great choices for signs in busy spots where people pass through all day long. Their lasting power means businesses can keep their branding visible without constant worries about replacement. Some studies show these plastic signs stand up to sun damage and scratches far better compared to old school materials like wood or metal. Retail stores especially notice this difference when they switch over. Not only do customers see the logos clearer for longer periods, but shop owners save money on repairs too since acrylic doesn't break down so easily even under tough conditions outside or inside crowded spaces.

Marine-Grade Applications in Harsh Environments

Marine grade acrylic sheets really shine when it comes to resisting saltwater damage, which is why boat builders and dock manufacturers often go this route instead of cheaper alternatives that tend to rot away after just a few seasons. Look at any fishing vessel or seaside restaurant deck these days and chances are good they're using some form of acrylic material that holds up against constant exposure to seawater and UV rays. Studies across various maritime projects consistently show acrylic outperforming options like fiberglass or metal alloys over time. Boats fitted with acrylic components last longer before needing repairs, and coastal installations maintain their appearance far better than those constructed from conventional materials, even through years of pounding waves and fluctuating temperatures.

Sustainability in Acrylic Board Manufacturing

Recycled Content and Circular Production Models

More and more top acrylic producers are starting to mix recycled content into their manufacturing operations, which supports the circular economy concept. The benefits go beyond just cutting down on waste - it actually cuts way back on resource usage too, so the whole production cycle becomes greener. Looking at recent sustainability data shows pretty clearly that when companies use recycled acrylic instead of virgin material, they slash their environmental footprint because they don't have to extract so many new resources. With buildings getting stricter green standards all the time, especially in commercial construction projects, companies that switch to these circular methods find themselves better equipped to handle client requests for eco-friendly specs. This gives them a real edge in markets where sustainability credentials matter.

Reduced Carbon Footprint vs. PVC Alternatives

When it comes to sustainability, acrylic boards beat out PVC alternatives hands down. They just produce way less carbon during manufacturing and last much longer before needing replacement. Research on lifecycle emissions shows acrylic manufacturing releases significantly fewer greenhouse gases compared to traditional PVC processes. That's why we're seeing this shift happening worldwide towards greener options. Architects working on LEED certified buildings often specify acrylic instead of PVC because they know clients care about environmental impact these days. The construction industry is slowly but surely moving away from old school materials as specs start demanding more eco friendly alternatives across all project types.

Compliance with Global Green Building Standards

A lot of acrylic products actually fit within international green building standards, which helps architects and construction teams get those important certifications like LEED (Leadership in Energy and Environmental Design). Looking at recent certification numbers shows more and more building projects are now using acrylic materials as part of their strategy to hit sustainability targets. When builders choose materials that match these global standards, it makes the whole project look better on paper and shows they really care about building responsibly from an environmental standpoint. The growing popularity of these materials speaks volumes about how seriously the construction industry is taking sustainability these days, especially since clients increasingly want buildings that have lower environmental impacts throughout their entire lifecycle.

Innovations from Leading Acrylic Sheet Manufacturers

Anti-Graffiti and Self-Cleaning Surface Treatments

Top acrylic sheet makers are coming up with special surface coatings that stop graffiti from sticking and keep the material clean on its own. These new treatments address a big problem for city areas where vandals often spray paint everywhere because the graffiti just won't adhere to the treated surfaces anymore. Maintenance crews save tons of money since they don't need to spend hours scraping off graffiti anymore. Plus, there's also technology that makes the sheets resistant to dirt buildup. Cities that started using these treated acrylics report spending way less on regular cleaning and seeing fewer acts of vandalism overall. The results speak for themselves when looking at subway stations or bus shelters that stay looking fresh without constant upkeep, which is why more municipalities are adopting these solutions for their public infrastructure projects.

Integration with Smart Building Technologies

Smart buildings are pushing acrylic sheets into new territory, transforming how they fit into architectural designs today. When manufacturers start adding things like LED lighting and sensors right into the material itself, these sheets become much more than just decorative elements. They actually help create smarter spaces where everything works better together. The whole thing makes sense when we look at how fast IoT devices have taken off recently. Now architects can easily slot acrylic components into their smart systems without major headaches. What makes acrylic so special? Well, its flexibility means it adapts well to whatever cities need next as they grow and change shape over time. Some big names in construction have already seen results from this approach, noting that buildings incorporating these advanced acrylic features tend to run smoother day to day while also looking great on paper during planning stages.

Customizable Mirror Acrylic for Design Applications

Mirror acrylic sheets that can be customized are changing how designers approach their work, giving architects something pretty special to play with when creating those reflective surfaces throughout different projects. They work just as well inside buildings as outside, providing nice looks while actually holding up structures too. Think about those amazing wall panels in hotels or those fancy ceiling installations in museums that really grab people's eyes. Designers love working with these materials because they let creativity run wild. A recent survey showed over 70% of architects have started incorporating custom mirrors into their latest builds, making bold statements that stand out in today's architectural landscape.

Selecting Reliable Aluminium Composite Panel Suppliers

Quality Certifications to Prioritize

Finding the right suppliers for aluminum composite metal panels means looking at their quality certifications first and foremost, especially ones like ISO 9001. These kinds of certifications show that a supplier actually cares about maintaining good quality control processes across their operations. For anyone working on construction projects, having proper documentation to prove these certifications isn't just paperwork it's essential for meeting building codes and giving clients peace of mind too. The construction world can be pretty tough on materials, so this extra verification acts as insurance against problems down the road. Studies from various industry reports back this up showing that when projects use materials from certified vendors, both clients and contractors tend to be much happier with the results. That makes sense really because nobody wants surprises when dealing with something as critical as building materials.

Comparative Analysis of Load-Bearing Capacities

Before settling on any panel supplier, it pays to compare how much weight each can actually hold up. Skipping this step could lead to serious problems down the road, especially when dealing with things like building facades on skyscrapers where failure isn't an option. Take time to look at what specs each supplier throws out there about their products' strength ratings. This saves money in the long run by preventing expensive fixes later on and keeping everyone safe during construction. The construction industry has seen plenty of cases where companies rushed through this process only to regret it later. Proper evaluation isn't just good practice it's practically mandatory for anyone wanting their structures to stand tall without incident.

Fire-Retardant Options for Safety-Critical Projects

When working on projects where safety matters most, aluminum composite panels need to have proper fire retardant features to comply with regulations and reduce potential fire hazards. Contractors must ask suppliers for detailed information about fire safety certificates and how their materials perform under tough fire conditions during tests. Real world incidents show what happens when fire risks aren't properly controlled - buildings catch fire, people get hurt, insurance claims skyrocket. That's why specifiers should always go for panels that come with official fire retardant certification marks. Making these smart choices isn't just about ticking boxes on paperwork; it actually protects the whole construction from damage and keeps everyone inside safe during emergencies.

FAQ

What makes acrylic boards suitable for outdoor use?

Acrylic boards are suitable for outdoor use because of their superior UV resistance, remarkable impact strength, and weatherproof qualities. These properties ensure durability and longevity in various environmental conditions.

How does acrylic compare to aluminum composite panels?

Acrylic offers cost-effectiveness in long-term maintenance, aesthetic versatility, and superior thermal stability compared to aluminum composite panels. These factors make acrylic a preferred choice for sustainable and innovative architectural designs.

Are acrylic sheets environmentally friendly?

Yes, acrylic sheets are environmentally friendly. They are increasingly manufactured with recycled materials, have a reduced carbon footprint compared to PVC, and meet global green building standards, contributing to sustainable practices.

How do acrylic sheets integrate with smart building technologies?

Acrylic sheets integrate with smart building technologies by incorporating energy-efficient lighting and sensing elements, enhancing operational efficiency and enabling the creation of intelligent environments in modern architecture.

Table of Contents

- Acrylic Board Advantages for Outdoor Durability

- Competitive Edge Over Aluminum Composite Metal Panels

- Critical Outdoor Applications of Acrylic Sheets

- Sustainability in Acrylic Board Manufacturing

- Innovations from Leading Acrylic Sheet Manufacturers

- Selecting Reliable Aluminium Composite Panel Suppliers

- FAQ